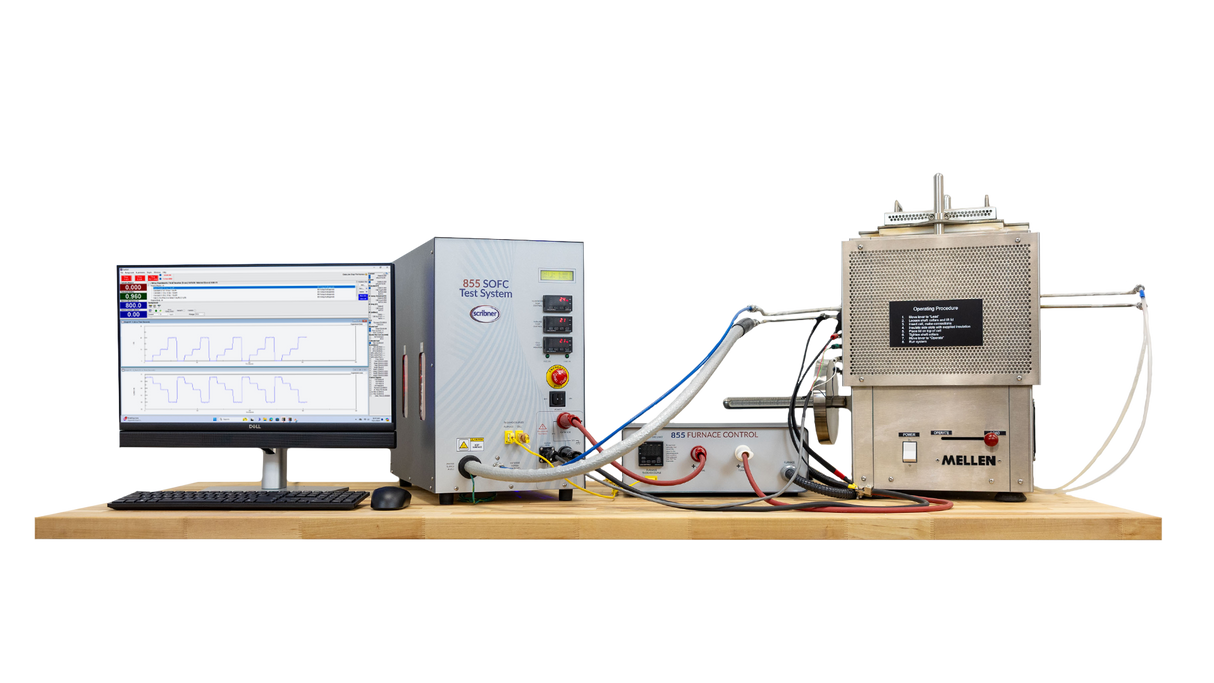

855 SOFC & SOEC Test System

Impossibile caricare la disponibilità del ritiro

Consegna e spedizione nell'UE

Consegna e spedizione nell'UE

Nel preventivo aggiungeremo i costi di spedizione, assicurazione e sdoganamento.

855 SOFC & SOEC Test System

Scribner

Scribner’s 855 Solid-Oxide Fuel Cell (SOFC) and Solid Oxide Electrolysis Cell (SOEC) Test System, is designed to support your testing needs. Capable of zero-volt applications for lower measurement range, as well as automated, hands-free switching between SOFC and SOEC mode via FuelCell® software. The 855 is known for it’s high performance and accuracy.

FuelCell® Software and Experimental Methods Manual are included. Optional Impedance Spectroscopy & HFR.

- Suitable for Button Cells and Planar Cells

- Multi Range Electronic load 5/25/50 A, 100 W, 20 V

- FuelCell® software for user-friendly computer controlled cell operation & experimentation

- Stainless Steel Anode humidifier with Bypass Valve and auto waterfill

- Programmable Power Supply for SOEC mode operation – 100 A / 5 V

- Power Supply mode includes Voltage & Current control with Constant, Scanning & Step-Stair experiments

- Up to five mass flow controllers available

- Includes Furnace Control hardware with redundant over-temperature protection

- Constant or stoichiometric-controlled reactant flow rate

- Zero Volt Capability

- Current, voltage or power control mode

- Continuous real time cell resistance and IR-free voltage measurement by Current Interrupt

- Whole cell voltage plus two high-impedance reference inputs for half-cell data

- Cell main terminals & sense inputs tolerant of non-isolated cell

- Safety features include detection of alarm conditions and automatic hardware shutdown for safe, reliable operation

| Specification: | Details |

|---|---|

| Electronic Load: | |

| Maximum Load Current: | 5/25/50 A |

| Maximum Load Power: | 100 W |

| Minimum Load Resistance: | < 2 mΩ (100 mV @ 50 A at load terminals) |

| Current Resolution: | 1 mA for 5/25/50 A |

| Current Accuracy: | 0.3 % of full scale current rating |

| Voltage Measurement and Data Acquisition: | |

| Maximum Whole Cell Voltage: | 20 V |

| Maximum Reference Electrode Voltage: | 9.999 V |

| Sense Lead Input Resistance: | > 35 kΩ |

| Voltage Resolution: | I mV |

| Voltage Accuracy: | ±3 mV ±0.3 % of reading |

| Voltage and Current Data Update Rate: | 100 Hz |

| Reactant Gas Control System: | |

| All 316 stainless steel construction of humidifiers, flow path, valves and mass flow controllers, with Swagelok® fittings | |

| Mass Flow Control: | Up to 5 SLM H2 (Anode) and 10 SLM Air (Cathode). *Software controlled mass flow controllers. Automatic N2 purge valves on anode and cathode |

| Alarm Inputs: | Gas supply pressures (3), humidifier water level (1), furnace over temperature (1), and external (1) |

| Temperature Controllers: | |

| Quantity: | (3) Furnace, anode humidifier, cell temp |

| Set and Report Accuracy: | ±0.25 % of span, ±1 least significant digit |

| Sensor Type: | Thermocouple, type K (R/S also available) |

| Temperature Limit Controller: | (1) Furnace over-temp |

| Humidifier: | Anode only, sparger-type, single passivated 316L W heaters per bottle |

| Temperature Range: | Ambient to 99 ° C |

| Automated humidifier bypass | |

| Environment: | |

| Operating Temperature: | 0 - 40 °C |

| Power Source: | 120 V, 50/60 Hz, 900 W |

| Enclosure Type: | Single bench top enclosure |

| Size and Weight: | 18” H x 11” W x 19” D, 50 lb |

| 46 cm x 28 cm x 48 cm, 23 kg | |

| Safety Features: |

Automatic shutdown and N2, purge with under voltage, over-current, over-temperature, loss of reactant or purge gas pressure, furnace over-temperature limit, communications failure or external alarm. manual emergency stop switch included for manual shutdown by operator. |