ETB Pure Series - Plastic Universal Research Electrolyser

Impossibile caricare la disponibilità del ritiro

Consegna e spedizione nell'UE

Consegna e spedizione nell'UE

Nel preventivo aggiungeremo i costi di spedizione, assicurazione e sdoganamento.

ETB Pure Series - Plastic Universal Research Electrolyser

Materials Mates Italia

Rising the level of features

performances and safety, the

ETB Pure stations offer all you need for your studies on electrolysis in a single, compact system.

ü PEM, AEM, ALKALINE models

ü FIRST all plastic pressurized test bench to grant the ultimate chemical purity

ü Complete gas and water management

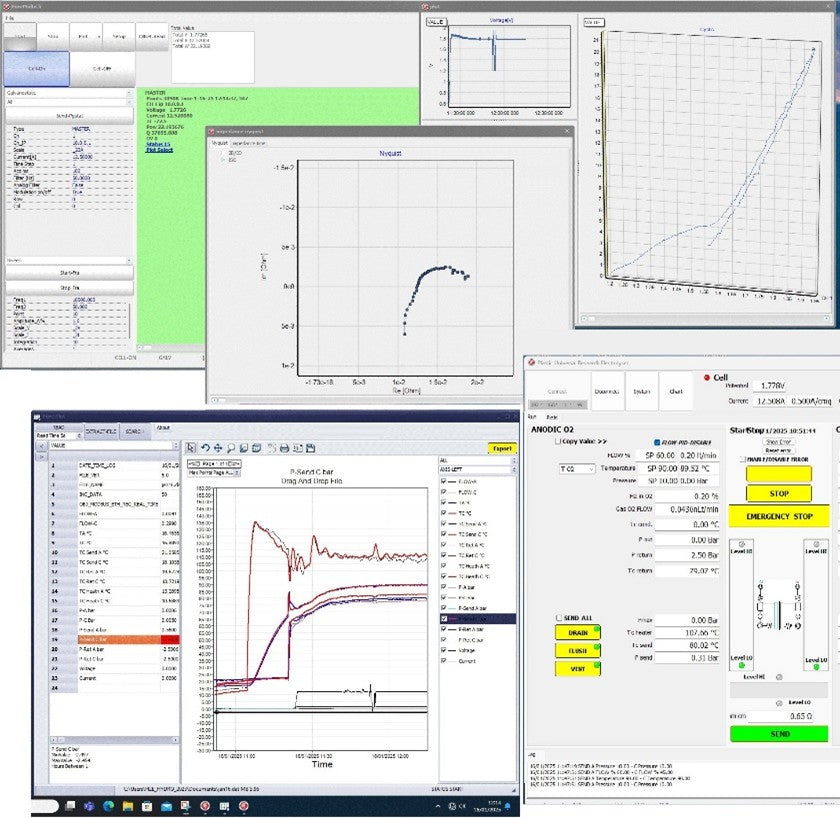

ü High power electrical testing including EIS,

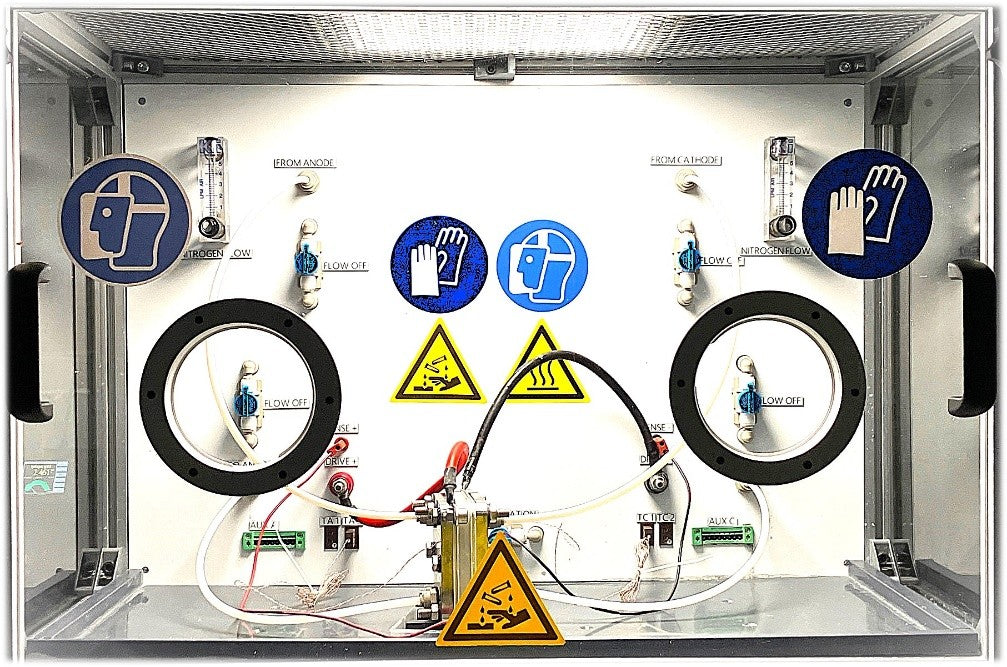

ü Safe and clean testing area cell mounting area to protect the operator

ü Complete SW suite for DC and AC complex tests and sequences

ü Automatic refill and simple liquid management even in presence of aggressive fluids

ü Small footprint floor standing or table-top to fit any lab space

Electric

Suitable for cells and stacks, up to 1KW of applied DC power / High accuracy Cell power supply up to 200 A

Complete software control of the tests with optional EIS in the range 1 mHz-10 KHz @ full power .

Thermal

Cell water operating temperature to 85°C / High long and short term thermal stability Control loop referenced to different temperature sensors for outstanding accuracy on the sample

Pressure

Max cell operating pressure 5 Bar / Closed loop backpressure control in the 1-5 bar range or atmospheric

Pressure readout 0-6 Bar / Certified , overpressure safety valve for ultimate safety

Mass analysis

Proprietary volumetric produced gas meter, insensitive to moisture and pollutants

Water circulation measure / Cross leak sensors / accessible calibration gas inputs

Water circuit

All plastic surfaces in contact with the electrolyte grants for liquid purity/ Fully symmetrical design for anodic and cathodic circuits Compatible with highly concentrated KOH solutions and ultrapure water (deionizing circuit + bypass on PEM systems) Pulsation-free pump circulation and flow metering to 1lt/ min / Continuous in-flow conductivity meter for KOH concentration recording / High pressure refill pump with DI water refill tank for continuous operations.

KOH solution handling connections for easy and safe refill/conductivity adjustment

Safety circuits

O2 / H2 mixture proprietary safety detectors on both anodic and cathodic output/ Explosive gases sensor placed in exhaust duct with 10 % LEL threshold to grant NON ATEX environment/ Nitrogen flushing system with independent actions on the two sides and check valves / Exhaust fan, inner construction for depression protection of outer environment /6 mm thick protection windows and Interlock signals safety for connection with internal / external safety circuits of the lab

measurements

Complete recording of all operating temperatures, pressures, flow, and other parameters with real-time visualization and comparison of old and new data.

Interface for our proprietary Pstat/Gstat or in junction with all the major suppliers of Potentiostats