ETB Pure Series - Plastic Universal Research Electrolyser

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

ETB Pure Series - Plastic Universal Research Electrolyser

Materials Mates Italia

Rising the level of features

performances and safety, the

ETB Pure stations offer all you need for your studies on electrolysis in a single, compact system.

ü PEM, AEM, ALKALINE models

ü FIRST all plastic pressurized test bench to grant the ultimate chemical purity

ü Complete gas and water management

ü High power electrical testing including EIS,

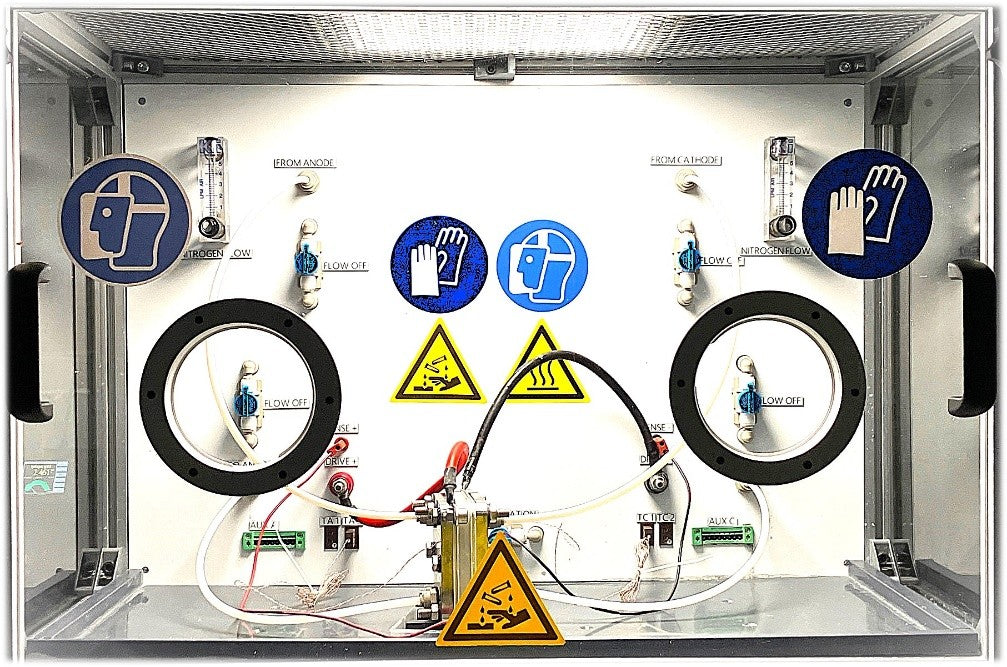

ü Safe and clean testing area cell mounting area to protect the operator

ü Complete SW suite for DC and AC complex tests and sequences

ü Automatic refill and simple liquid management even in presence of aggressive fluids

ü Small footprint floor standing or table-top to fit any lab space

Electric

Suitable for cells and stacks, up to 1KW of applied DC power / High accuracy Cell power supply up to 200 A

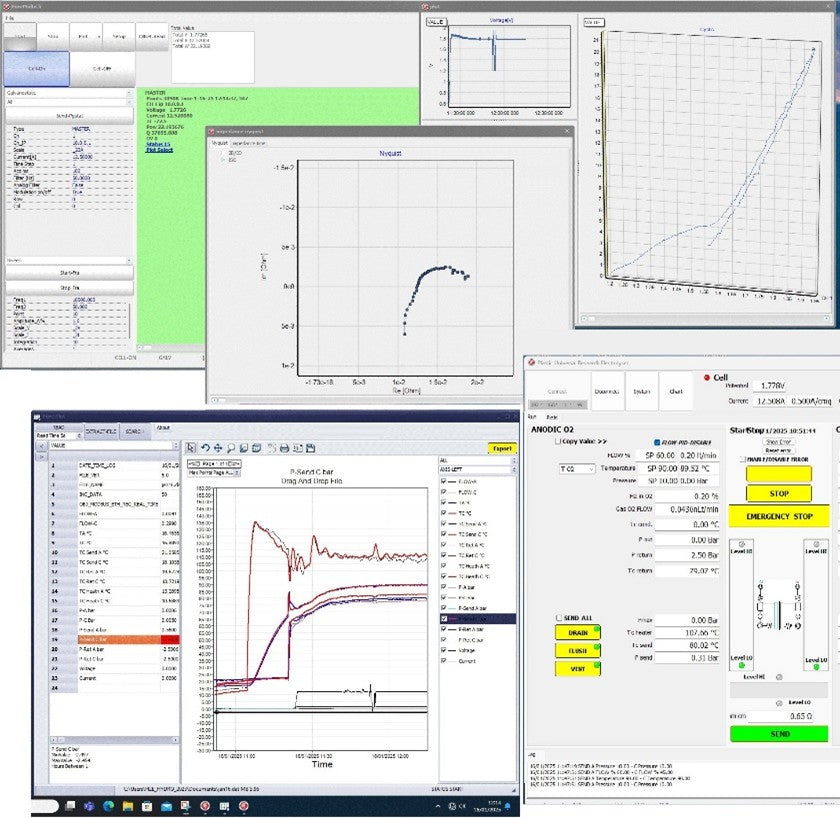

Complete software control of the tests with optional EIS in the range 1 mHz-10 KHz @ full power .

Thermal

Cell water operating temperature to 85°C / High long and short term thermal stability Control loop referenced to different temperature sensors for outstanding accuracy on the sample

Pressure

Max cell operating pressure 5 Bar / Closed loop backpressure control in the 1-5 bar range or atmospheric

Pressure readout 0-6 Bar / Certified , overpressure safety valve for ultimate safety

Mass analysis

Proprietary volumetric produced gas meter, insensitive to moisture and pollutants

Water circulation measure / Cross leak sensors / accessible calibration gas inputs

Water circuit

All plastic surfaces in contact with the electrolyte grants for liquid purity/ Fully symmetrical design for anodic and cathodic circuits Compatible with highly concentrated KOH solutions and ultrapure water (deionizing circuit + bypass on PEM systems) Pulsation-free pump circulation and flow metering to 1lt/ min / Continuous in-flow conductivity meter for KOH concentration recording / High pressure refill pump with DI water refill tank for continuous operations.

KOH solution handling connections for easy and safe refill/conductivity adjustment

Safety circuits

O2 / H2 mixture proprietary safety detectors on both anodic and cathodic output/ Explosive gases sensor placed in exhaust duct with 10 % LEL threshold to grant NON ATEX environment/ Nitrogen flushing system with independent actions on the two sides and check valves / Exhaust fan, inner construction for depression protection of outer environment /6 mm thick protection windows and Interlock signals safety for connection with internal / external safety circuits of the lab

measurements

Complete recording of all operating temperatures, pressures, flow, and other parameters with real-time visualization and comparison of old and new data.

Interface for our proprietary Pstat/Gstat or in junction with all the major suppliers of Potentiostats