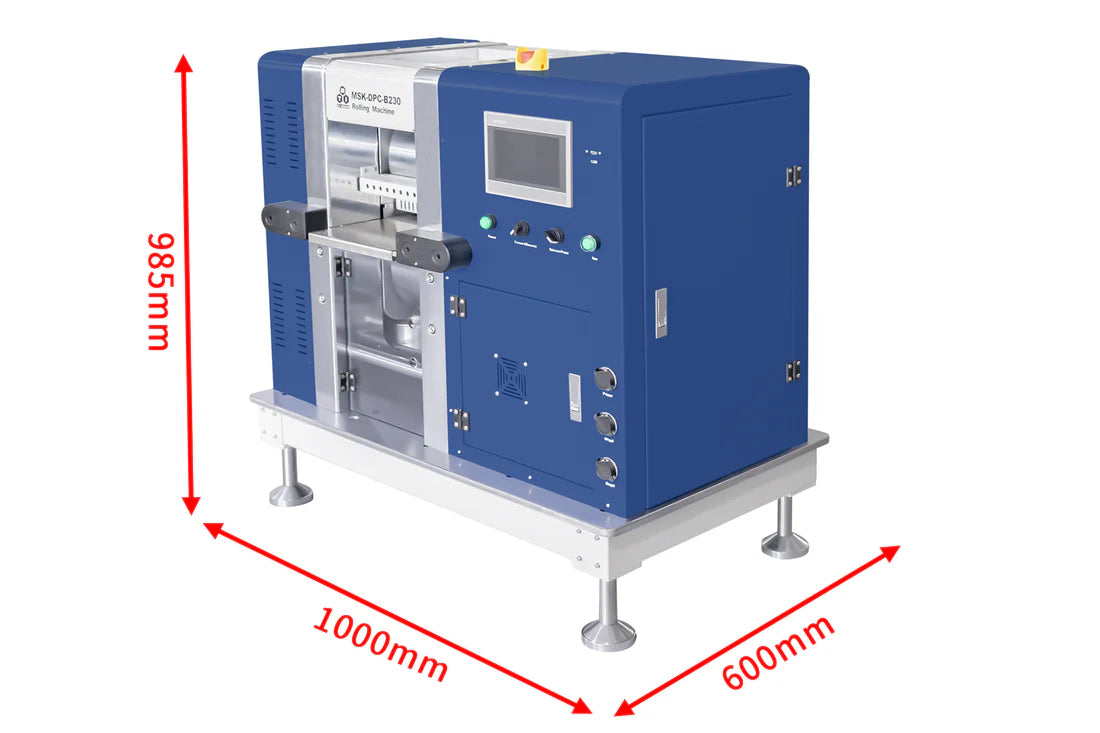

80T Max. Pressure Controlled Rolling Machine (220 mm W x 230 mm Dia.) for Battery Electrodes-MSK-DPC-B230

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

80T Max. Pressure Controlled Rolling Machine (220 mm W x 230 mm Dia.) for Battery Electrodes-MSK-DPC-B230

MTI

MSK-DPC-B230 is a precision electric calendar machine (rolling press) with a high-quality hydraulic pressure controllable system. It can prepare electrode sheets (current collector with the active material coated on it) at consistent and repeatable rolling pressure up to 80T. The super high rolling pressure enable to achieve high compaction density for electrodes.

SPECIFICATIONS:

|

|

|

|

Max. Power Consumption |

|

|

Rollers (One pair) |

|

| Max. Rolling Pressure |

|

| Press Gap |

|

| Motor & Rolling Speed |

|

|

Press Planeness |

|

|

Compressed Air |

pic1 pic1  pic2 pic2

|

| Optional |

|

|

Compliance |

|

|

Application Notes |

|