MTI | SKU:

DIE01D

Φ1mm (I.D) Customizable Pellet Pressing Die-Die01D

€0,00

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Φ1mm (I.D) Customizable Pellet Pressing Die-Die01D

MTI

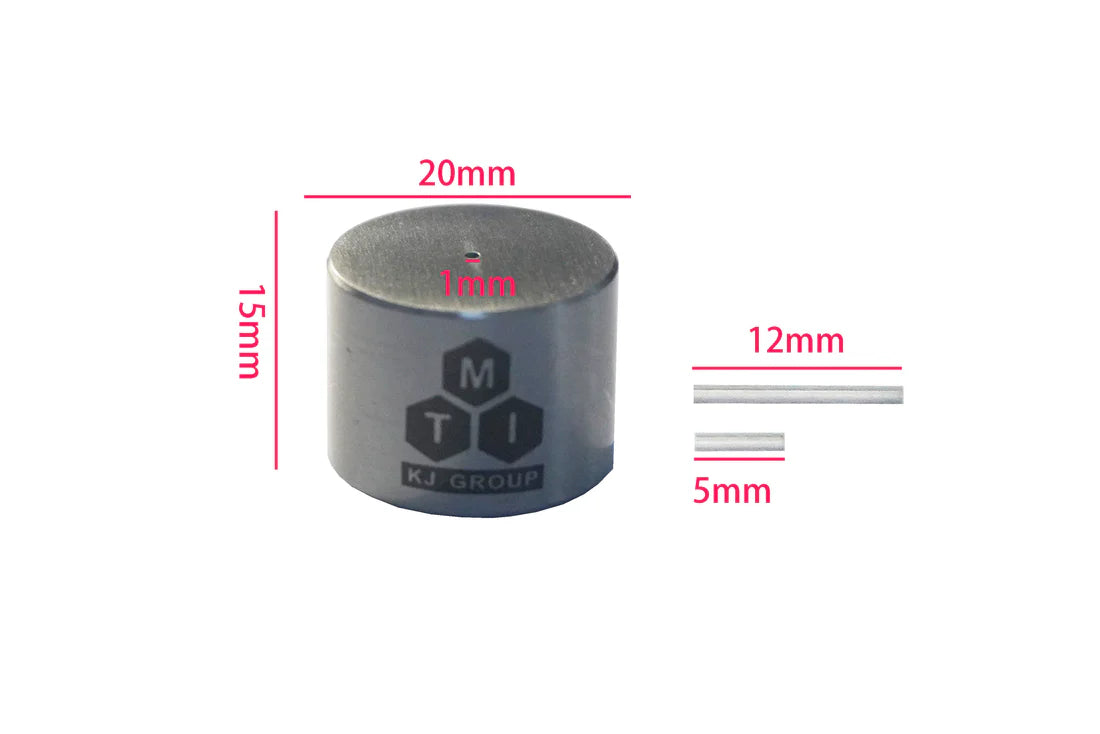

Die01D is a 1mm Inner Diameter Pellet Pressing Die for making a 0.1-6 mm height cylindrical sample. The pressing die is made of high-hardness, high-strength and high temperature resistant steel material to meet various customers’ needs.

SPECIFICATION:

| Inner Diameter | Φ1mm |

|

Product Dimensions |

|

| Maximum Load |

|

| Material |

|

| Sample Material Requirement |

|

| Safety Precaution |

|

| Application Note |

|