Ultrasonic Spray Pyrolysis Furnace (4" Tube & Spray Nozzle and Powder Feeder) OTF-1200X-II-VT-USPA

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Ultrasonic Spray Pyrolysis Furnace (4" Tube & Spray Nozzle and Powder Feeder) OTF-1200X-II-VT-USPA

MTI

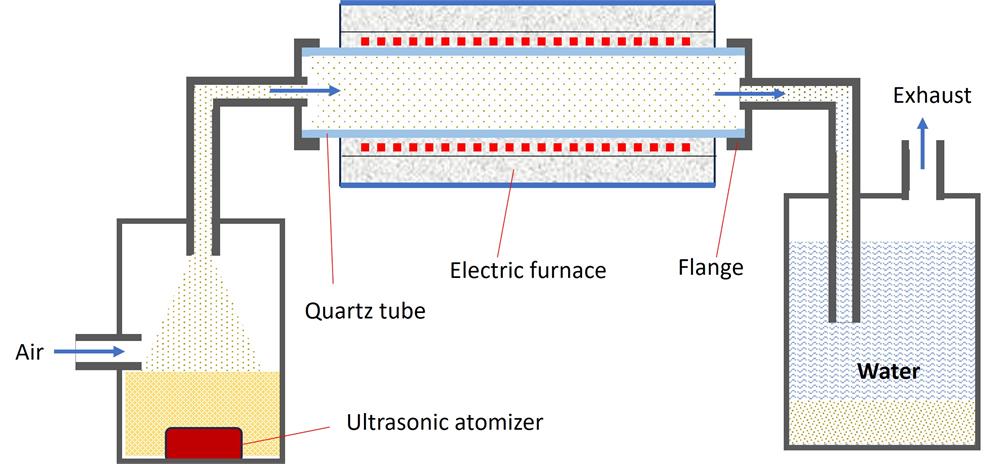

OTF-1200X-II-VT-USPA is Two Heating Zone Split Vertical Tube Furnace with a vacuum-sealed 100mm diameter quartz tube. It can introduce gas flow or liquid/ water atomization to the heating furnace, also be used for PVD, CSS or CVD coating. Two precision temperature controllers provide 30 segments heating and cooling program with +/- 1°C accuracy independently. The vertical tube furnace is installed in a heavy-duty mobile cart for easy moving.

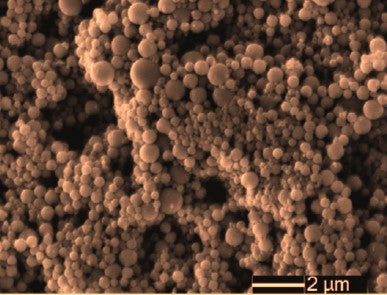

Related Article: Large scale production of spherical WO3 powder with ultrasonic spray pyrolysis assisted by sol-gel method for hydrogen detection

SPECIFICATIONS:

|

Furnace Structure |

|

| Power for Furnace | 6KW (total) / each zone: 3KW |

| Voltage | AC 208-240V Single Phase, 50/60 Hz |

| Max. Temperature | 1200°C (<1 hr) each zone |

| Continuous Temperature | 1100°C for each zone |

| Max. Heating Rate | <= 20°C/min. |

| Temperature Accuracy | +/- 1°C |

|

Tube Size and Materials |

|

|

Heating Zone Length |

|

| Constant Temperature Zone |

|

| Temperature Controller |

|

Vacuum Sealing Flange

|

|

|

Vacuum Level |

|

| Heating Element | 1300°C Fe-Cr-Al Alloy doped by Mo |

| Laptop, Software & WiFi Control (Optional) |

|

| Compliance |

|

| Application Note |

|

| Warning |

|