Evaporation coater in Glovebox for 4" Wafer with 3 Crucible & Temperature Control - VTC-EV3-GB

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Evaporation coater in Glovebox for 4" Wafer with 3 Crucible & Temperature Control - VTC-EV3-GB

MTI

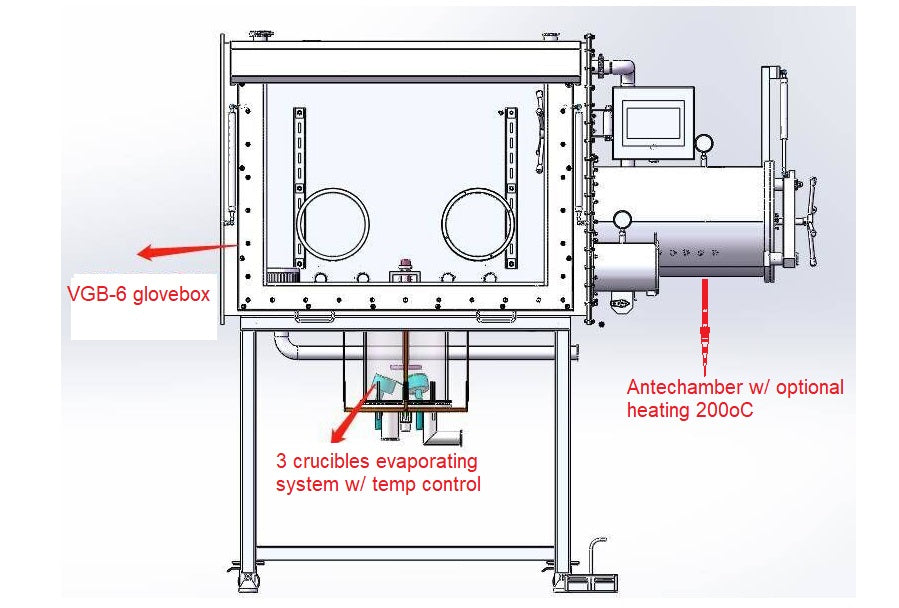

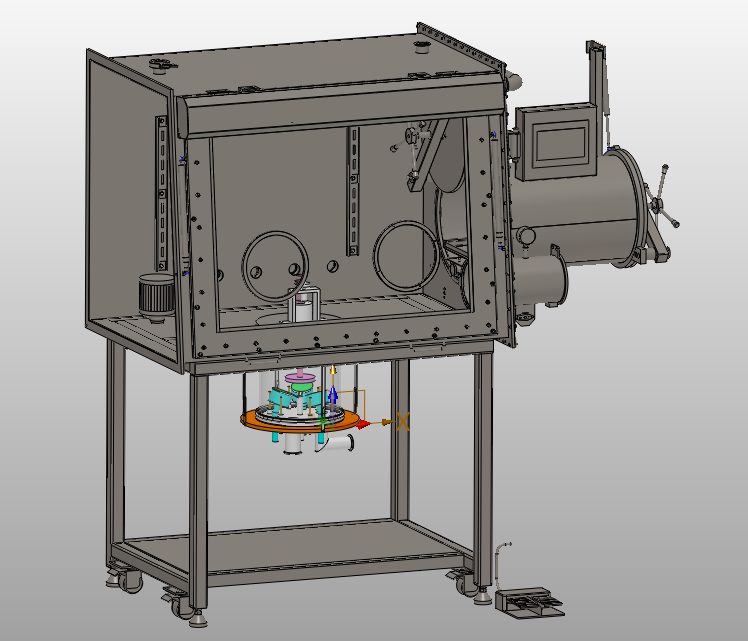

VTC-EV3-GB is a thermal evaporating system in the glovebox with a total of 3 evaporating sources and precision temperature control. Three evaporating crucibles could be used to grow multilayer films one by one in the same chamber atmosphere. The system is suitable for coating most of the film of the metallic and organic material up to 4" in size from 200 ºC - 1700 ºC with a B-type thermocouple.

SPECIFICATIONS:

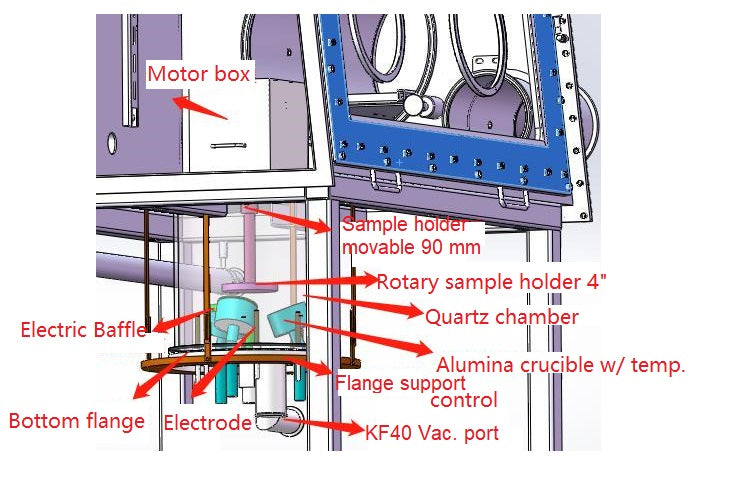

Structure & Features

|

|

| Power |

|

| Temperature Control & Heaters |

Pic.1 Pic.1  PIC 2 PIC 2 |

| Rotatable Sample Holder |

|

| Film Thickness Analysis System |

|

| Vacuum |

|

| Gas Inlet |

|

| Optional |

|

| Quartz Chamber Dimension |

O.D.:280mm ( 11") I.D.: 260mm ( 10.2") Length: 310mm ( 12.2") Please click here to order the Quartz Chamber replacement. |

| Compliance |

|

Standard Package

|

Item No.

|

Description

|

Pic | Quantity |

|

Quartz chamber 280 mm OD (ID = 260 mm, L = 310 mm)

|

1

|

||

|

Alumina outer crucible set (lid, thermal block, bottom crucible) |

3

|

||

| SPC2-AC |

Alumina cone-shaped crucible (OD = 19.6 mm, L = 24.0 mm)

|

3

|

|

| PGC-554-LD |

Anti-corrosive capacitance diaphragm gauge & controller with power supply, up to 3.8E-5 Torr

|

Optional | |

| SPC2-TB |

Tungsten coil heater, 1 mm wire diameter

|

2 | |

|

B type thermocouple (at extra cost) - heating from 200 ºC - 1700 ºC

|

Optional

|