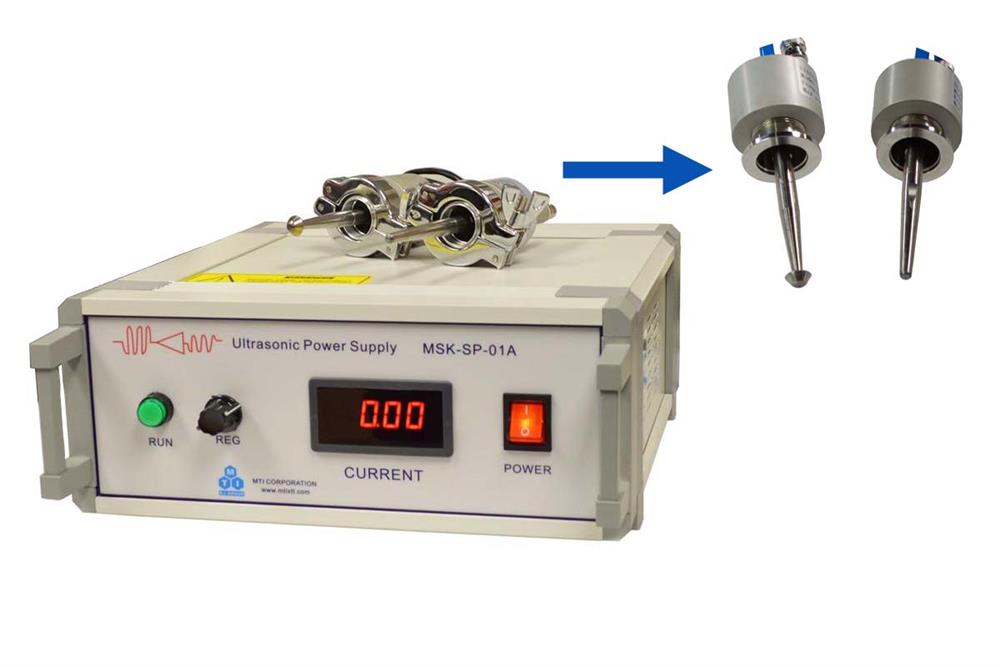

40KHz 130W Two Ultrasonic Spray Nozzles with Power Controller for DIY Spray Pyrolysis - MSK-SP-01A

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

40KHz 130W Two Ultrasonic Spray Nozzles with Power Controller for DIY Spray Pyrolysis - MSK-SP-01A

MTI

Ultrasonic spray utilizes ultrasonic energy to break liquid and form a few micron drop size. The ultrasonic spray nozzle can use low vibration energy to make liquid atomized via gravity and low-pressure compressed air. MSK-SP-01A is a 130 W, 40 kHz ultrasonic spraying nozzle with a power controller for DIY, low-cost spray pyrolysis coating in the material research lab. (Updated with digital current meter and KF25 adaptor since July 27, 2015)

| Ultrasonic Generator |

|

| Ultrasonic Converter |

|

| Converter Cable Length |

|

Spray Nozzle

|

Two Spray nozzles made of Titanium alloy (Ti-6Al-4V) with KF-25 Adapte (click left picture to see details)

|

Option |

|

| Average Drop Size |

|

| Shipping Weight & Dimensions |

|

| Compliance |

|

| Operation Demo Video |  How to Operate How to Operate  Spray Pattern Spray Pattern |

| Warranty |

|

| Optional |

Pic. 3 Pic. 3 Pic.4 Pic.4 Pic. 5 Pic. 5  Pic. 6 Pic. 6

|

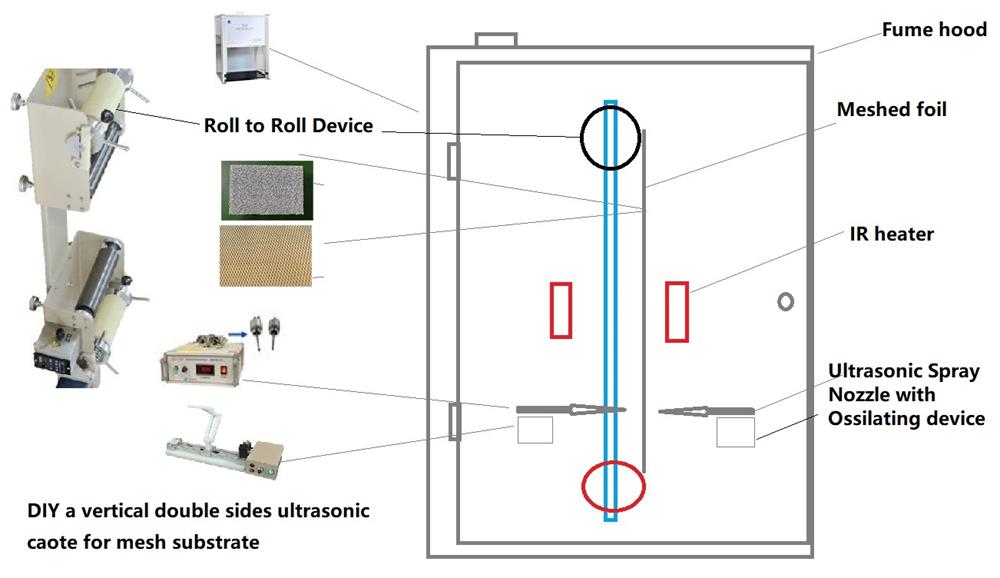

| DIY R2R Coaters |