MTI | SKU:

OTF1200XIISR2

Compact 2" Two Zone Rotary Tube Furnace @1100C Max For Powder CVD. - OTF-1200X-S-R-II

€0,00

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Compact 2" Two Zone Rotary Tube Furnace @1100C Max For Powder CVD. - OTF-1200X-S-R-II

MTI

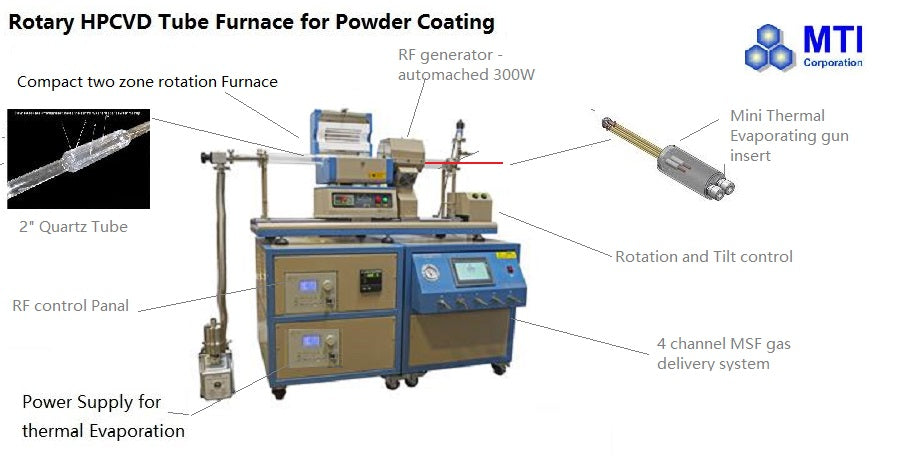

OTF-1200X-S-R-II is a compact two-zone rotary tube furnace with 2" quartz tube, designed for calcining inorganic compounds with better uniformity, especially good for preparing Li-ion battery cathode powders with conductive coatings.

Specifications:

|

Furnace Construction

|

|

|

Heating Zone length |

|

|

|

| Max. Working Temperature | 1100°C for continuously 1200 °C Max for < 2 hours |

|

Temperature Control

|

|

|

Tube rotating Speed

|

0 - 5 RPM variable

|

|

Furnace tilt angle

|

|

|

Chamber pressure

|

4.5x10-2 torr (<0.1mtorr/s leaking rate if close all the valves to airtight the tube chamber)

|

|

Power

|

1.5 KW Max

|

|

Voltage

|

|

| Warranty | One-year limited warranty (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Options (Click for more details) |

|

|

Compliance |

|

|

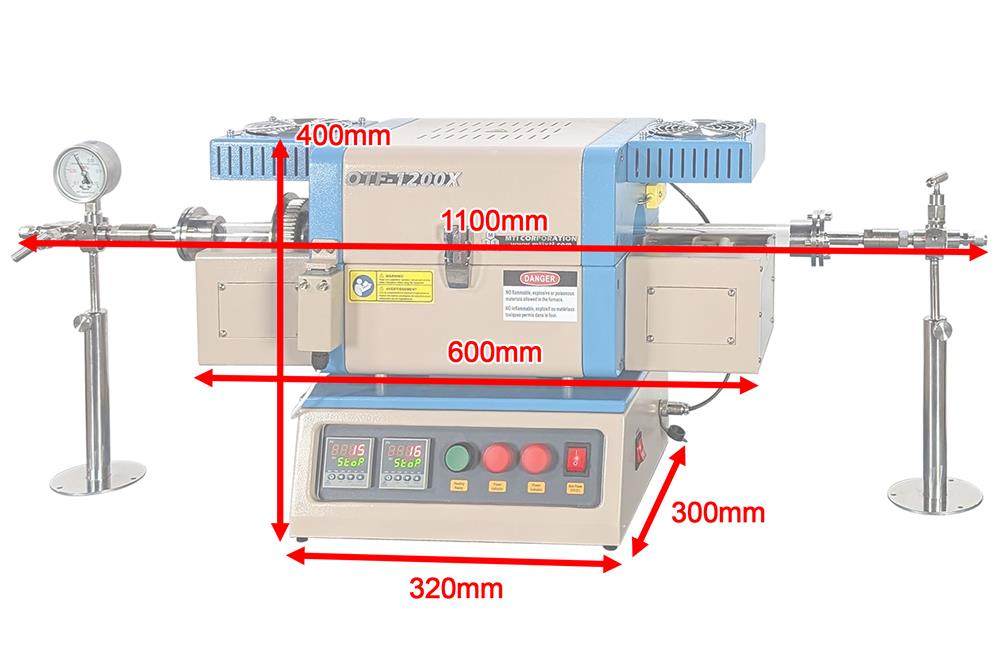

Furnace dimension:

|

|

|

Product net weight

|

25 Kg

|

| Shipping dimension | 40"x30"x35" |

| Shipping weight | 150 lbs |

| Operation Video |

|

| Warnings |

|