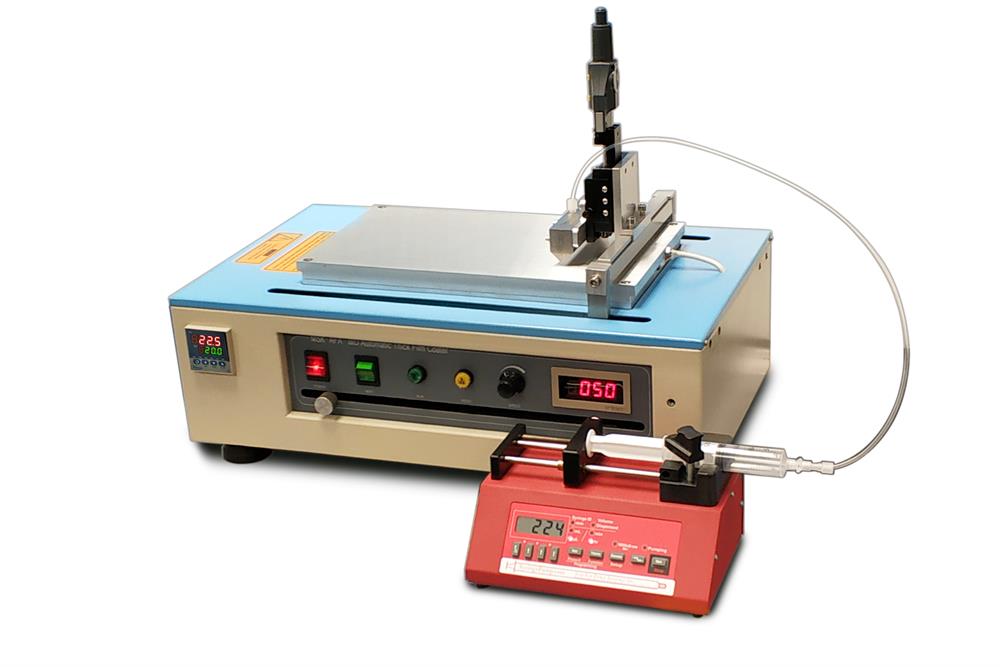

Economic Flat Slot Die Coater (optional 50 or 100mm Width) w/ Heating Vacuum Bed - MSK-AFA-III-FSC

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Economic Flat Slot Die Coater (optional 50 or 100mm Width) w/ Heating Vacuum Bed - MSK-AFA-III-FSC

MTI

MSK-AFA-III-FSC is an economic flat slot die with a 100mm coating head. It is an excellent tool to research film coating for perovskite solar cells, fuel cell proton exchange membrane, and the battery electrode.

SPECIFICATIONS

| Working Power |

|

Slot Died head

|

|

Syringe Pump

|

|

Micrometer Head

|

|

| Tavel Speed & Length |

|

| Heated Vacuum Bed \

|

|

| Options |

Pic. 1 Pic. 1 Pic. 2 Pic. 2 Pic. 3 Pic. 3  Pic. 4 Pic. 4  Pic. 5 Pic. 5 |

| Compliance | CE certified NRTL or CSA certification is available upon request at the extra cost |

|

Application Note |

|

| References |