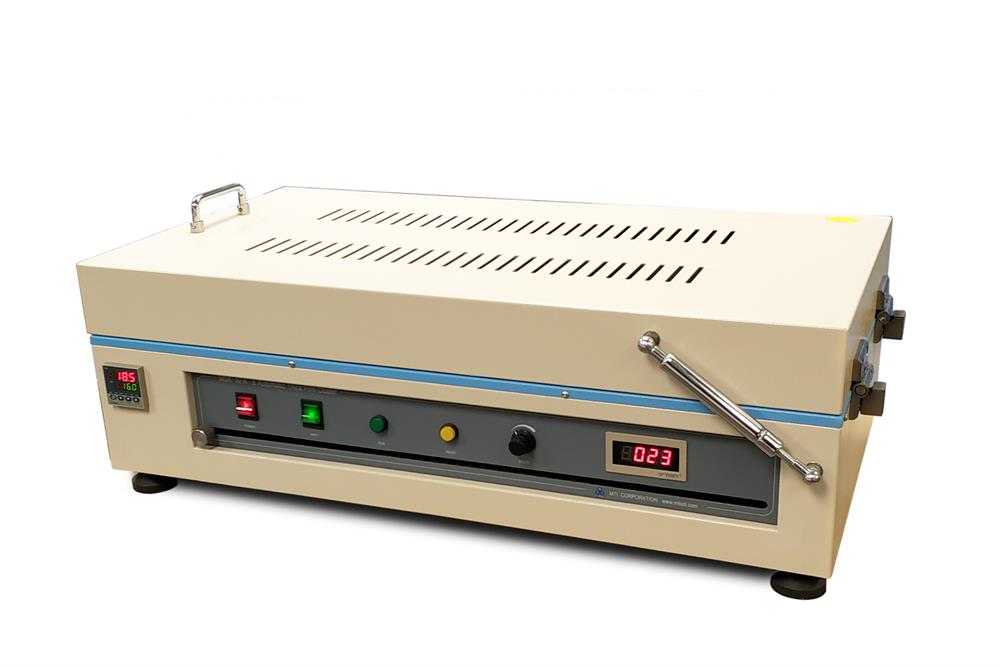

120°C Max. Film Coater w/ Heatable Vacuum Bed (12"Wx24"L) & 250mm Doctor Blade - MSK-AFA-II-VC-FH

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

120°C Max. Film Coater w/ Heatable Vacuum Bed (12"Wx24"L) & 250mm Doctor Blade - MSK-AFA-II-VC-FH

MTI

MSK-AFA-II-VC-FH is a CE Certified larger size automatic film coater with a Heat able vacuum bed up to 120ºC. It is designed to produce films with consistent thickness by using micrometer adjustable applicators or fixed thickness applicators. It has a stable driving system to promote a smooth coating with all types of materials. The pin holes on the bed can hold the substrate sheet on the bed via a vacuum. This is very helpful when performing coating on the thin substrate. It is an ideal tool for ceramic tape casting and Li-Ion battery electrode coating.

SPECIFICATIONS

| Working Voltage | 110VAC or 208~240VAC, 50/60Hz (please select one in the voltage option bar) |

| Max. Power Consumption | 2050W |

|

Traverse Speed |

|

| Stroke Length | 10 - 530 mm adjustable by using Adjustable Position Switch |

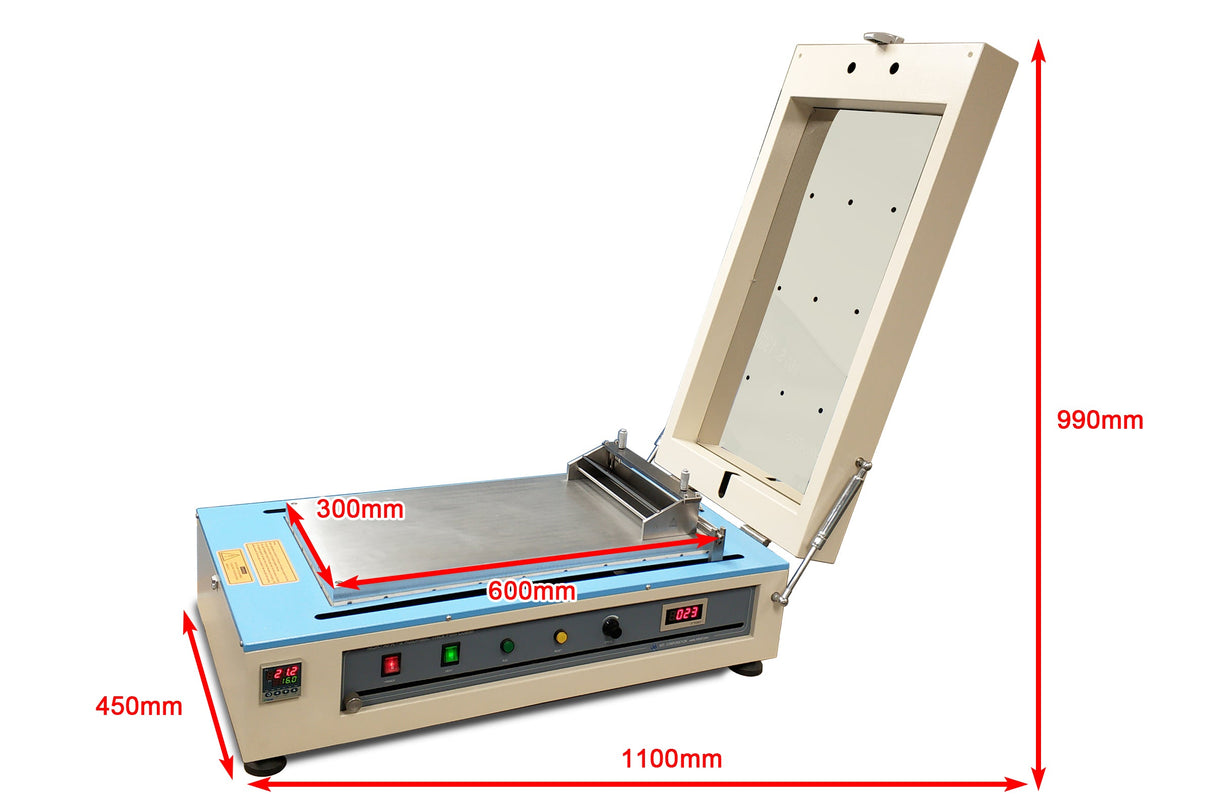

Heated Vacuum Bed

|

|

|

Pic. 1 |

|

| Vacuum Pump (Optional) |

|

| Compliance | CE certified NRTL or CSA certification is available upon request at the extra cost |

|

Application Notes |

Pic.1 Pic.2 Pic.3 Pic.4 |

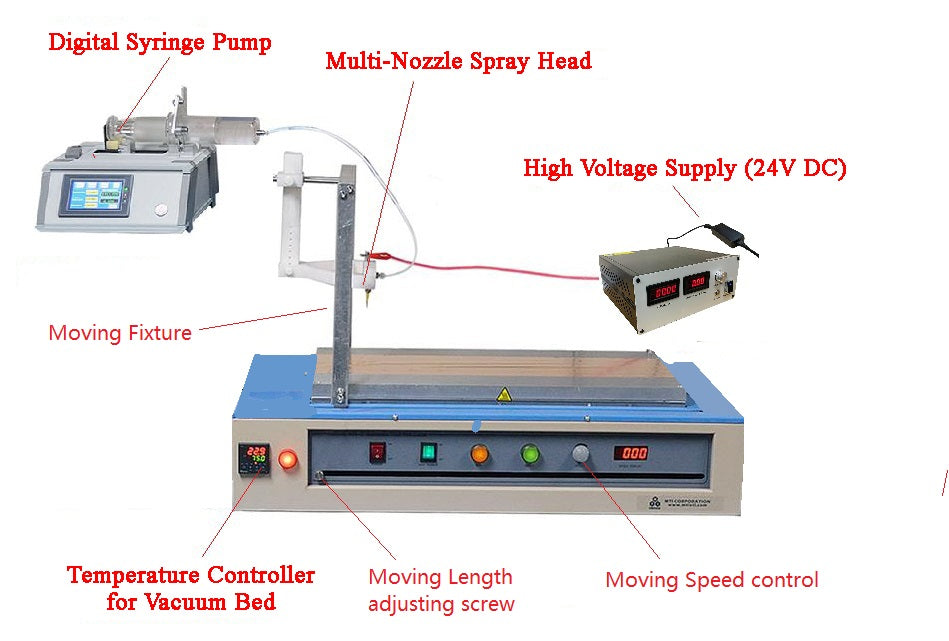

| DIY ideas or options |

Ultrasonic coater Roll to roll Electrospinning coater Roll to Roll |

STANDARD PACKAGE

| Item | Description | Qty |

| 1 | Large Automatic Film Coater | 1 |

| 2 | Traverse Pusher | 1 |

| 3 | Micrometer Adjustable Film Applicator - 250 mm (film casting doctor blade) EQ-Se-KTQ-250 | 1 |

| 4 | Power Cable (Note: 220V Power plug is not included. Please click here to order) | 1 |

| 5 | Waste Plate | 1 |

| 6 | 120L/min Oilless Vacuum Pump | optional |