Sheet Film Coater w/ Vacuum Chuck ( 300Wx600L mm) & 250mm Doctor Blade - MSK-AFA-II-VC

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Sheet Film Coater w/ Vacuum Chuck ( 300Wx600L mm) & 250mm Doctor Blade - MSK-AFA-II-VC

MTI

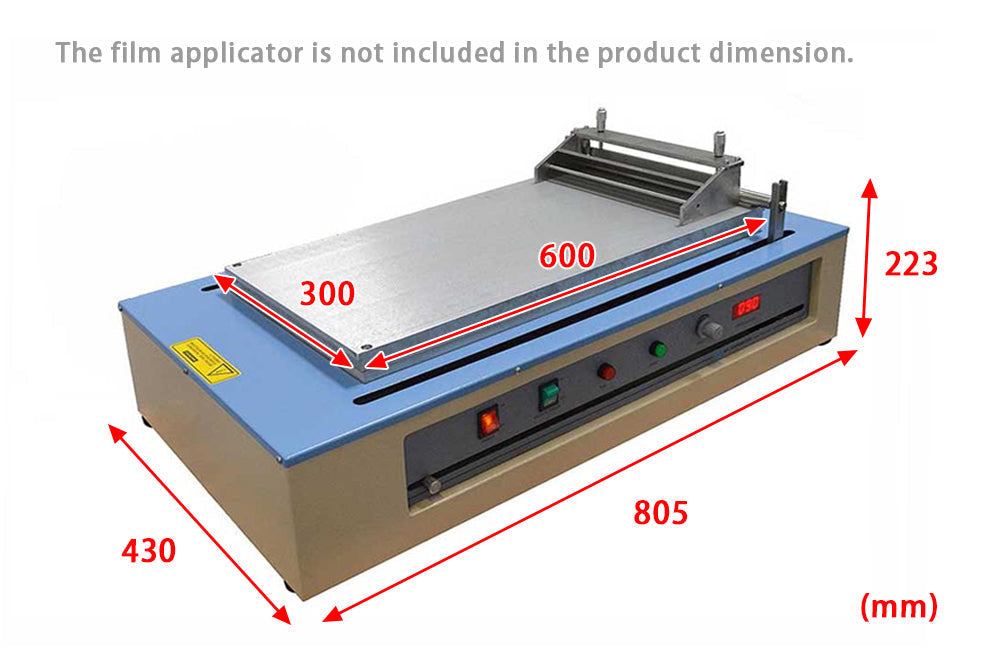

MSK-AFA-II-VC is a Large Automatic Film Coater with a Vacuum chuck ( 300 mm W x 600mm L) designed to produce films with consistent thickness by using thickness adjustable applicators. It has a unique driving system to produce a smooth coating on all types of materials. The vacuum chuck is built in to hold the substrate sheet in place, which is particularly useful when coating on the thin substrate and making uniform tape casting. One 250 mm width gap adjustable applicator is included. This machine can be used for research on SOFC and Li-Ion battery electrode coating.

SPECIFICATIONS

| Working Voltage |

INPUT: 24VDC One UL/CSAlisted 100-240VAC IN - 24VDC OUT power adapter is included. |

| Max. Power Consumption | 100W |

|

Traverse Speed |

|

| Stroke Length |

|

| Vacuum chuck |

|

|

Vacuum Pump (Optional) (Remove the oilless pump from the standard pack Since 02/26/2016 ) |

|

| Film Applicator |

|

| Compliance |

|

|

Application Notes |

Pic.1 Pic.2 Pic.3 Pic.4 Pic.5 |

STANDARD PACKAGE

| Item | Description | Qty |

| 1 | Large Automatic Film Coater | 1 |

| 2 | Traverse Pusher | 1 |

| 3 | Micrometer Adjustable Film Applicator - 250 mm (film casting doctor blade) EQ-Se-KTQ-250 | 1 |

| 4 | Power Cable (Note: 220V Power plug is not included. Please click here to order) | 1 |

| 5 | Waste Plate | 1 |

| 6 | 120L/min Oilless Vacuum Pump | optional |