300mm Width Slot-die Coater w/ SS316 Heating Vacuum Chuck (150°C, 500 L x 400mm W)-MSK-AFA-H500SD

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

300mm Width Slot-die Coater w/ SS316 Heating Vacuum Chuck (150°C, 500 L x 400mm W)-MSK-AFA-H500SD

MTI

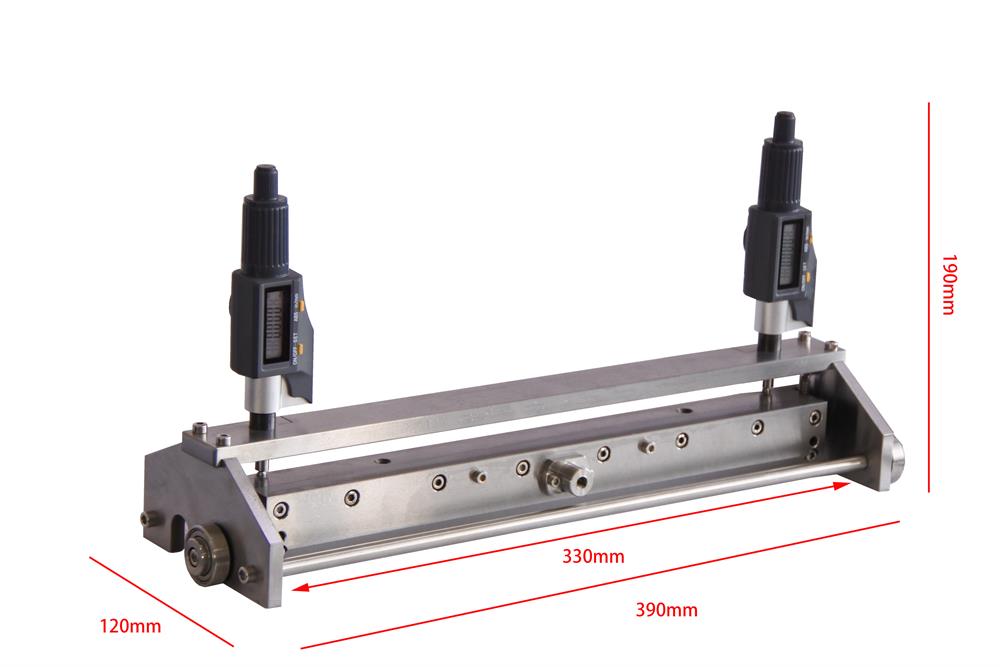

The MSK-AFA-H500SD is a flat slot-die coater that can coat films up to 400 mm L x 380 mm W from 5 to 100 microns thickness. It has a 500mm L x 400mm W vacuum chuck and bottom heater, and a special slot-die fixture with three precision rollers on the bottom to make slot-die coating uniform at low cost. This makes it an excellent tool for fabricating thin films for perovskite solar cells, fuel cells, and batteries.

The item number has been updated from MSK-SD-300 since February 2022

SPECIFICATIONS