855 SOFC & SOEC Test System

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

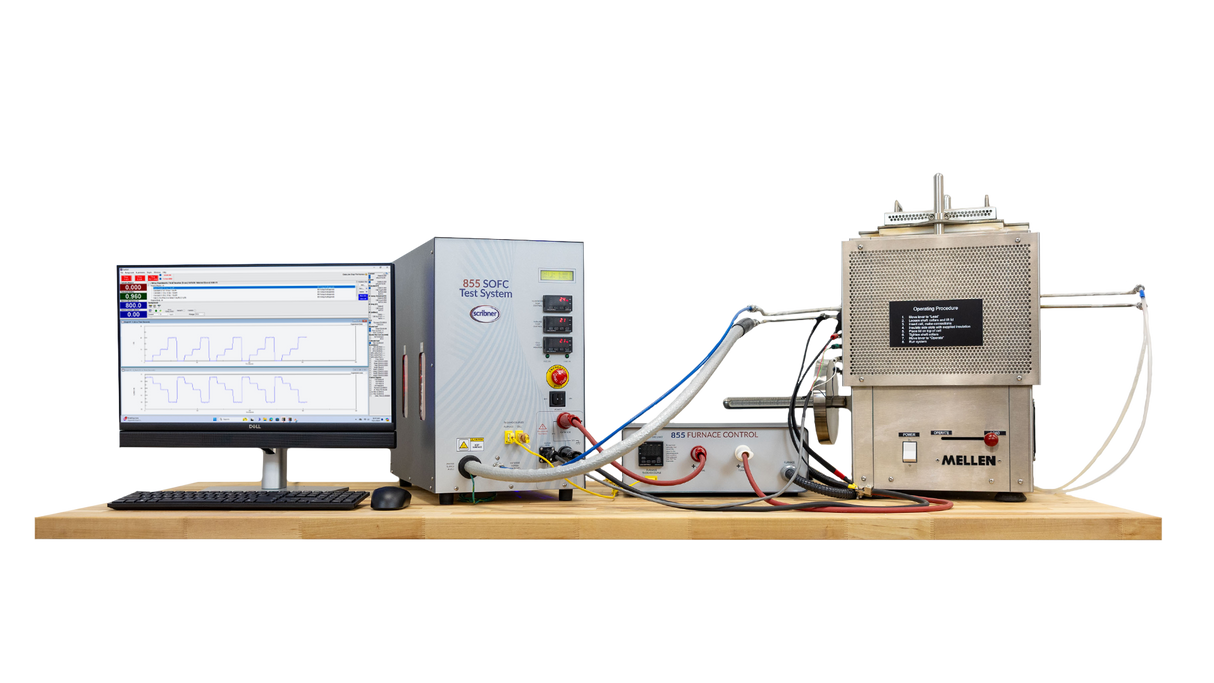

855 SOFC & SOEC Test System

Scribner

Scribner’s 855 Solid-Oxide Fuel Cell (SOFC) and Solid Oxide Electrolysis Cell (SOEC) Test System, is designed to support your testing needs. Capable of zero-volt applications for lower measurement range, as well as automated, hands-free switching between SOFC and SOEC mode via FuelCell® software. The 855 is known for it’s high performance and accuracy.

FuelCell® Software and Experimental Methods Manual are included. Optional Impedance Spectroscopy & HFR.

- Suitable for Button Cells and Planar Cells

- Multi Range Electronic load 5/25/50 A, 100 W, 20 V

- FuelCell® software for user-friendly computer controlled cell operation & experimentation

- Stainless Steel Anode humidifier with Bypass Valve and auto waterfill

- Programmable Power Supply for SOEC mode operation – 100 A / 5 V

- Power Supply mode includes Voltage & Current control with Constant, Scanning & Step-Stair experiments

- Up to five mass flow controllers available

- Includes Furnace Control hardware with redundant over-temperature protection

- Constant or stoichiometric-controlled reactant flow rate

- Zero Volt Capability

- Current, voltage or power control mode

- Continuous real time cell resistance and IR-free voltage measurement by Current Interrupt

- Whole cell voltage plus two high-impedance reference inputs for half-cell data

- Cell main terminals & sense inputs tolerant of non-isolated cell

- Safety features include detection of alarm conditions and automatic hardware shutdown for safe, reliable operation

| Specification: | Details |

|---|---|

| Electronic Load: | |

| Maximum Load Current: | 5/25/50 A |

| Maximum Load Power: | 100 W |

| Minimum Load Resistance: | < 2 mΩ (100 mV @ 50 A at load terminals) |

| Current Resolution: | 1 mA for 5/25/50 A |

| Current Accuracy: | 0.3 % of full scale current rating |

| Voltage Measurement and Data Acquisition: | |

| Maximum Whole Cell Voltage: | 20 V |

| Maximum Reference Electrode Voltage: | 9.999 V |

| Sense Lead Input Resistance: | > 35 kΩ |

| Voltage Resolution: | I mV |

| Voltage Accuracy: | ±3 mV ±0.3 % of reading |

| Voltage and Current Data Update Rate: | 100 Hz |

| Reactant Gas Control System: | |

| All 316 stainless steel construction of humidifiers, flow path, valves and mass flow controllers, with Swagelok® fittings | |

| Mass Flow Control: | Up to 5 SLM H2 (Anode) and 10 SLM Air (Cathode). *Software controlled mass flow controllers. Automatic N2 purge valves on anode and cathode |

| Alarm Inputs: | Gas supply pressures (3), humidifier water level (1), furnace over temperature (1), and external (1) |

| Temperature Controllers: | |

| Quantity: | (3) Furnace, anode humidifier, cell temp |

| Set and Report Accuracy: | ±0.25 % of span, ±1 least significant digit |

| Sensor Type: | Thermocouple, type K (R/S also available) |

| Temperature Limit Controller: | (1) Furnace over-temp |

| Humidifier: | Anode only, sparger-type, single passivated 316L W heaters per bottle |

| Temperature Range: | Ambient to 99 ° C |

| Automated humidifier bypass | |

| Environment: | |

| Operating Temperature: | 0 - 40 °C |

| Power Source: | 120 V, 50/60 Hz, 900 W |

| Enclosure Type: | Single bench top enclosure |

| Size and Weight: | 18” H x 11” W x 19” D, 50 lb |

| 46 cm x 28 cm x 48 cm, 23 kg | |

| Safety Features: |

Automatic shutdown and N2, purge with under voltage, over-current, over-temperature, loss of reactant or purge gas pressure, furnace over-temperature limit, communications failure or external alarm. manual emergency stop switch included for manual shutdown by operator. |