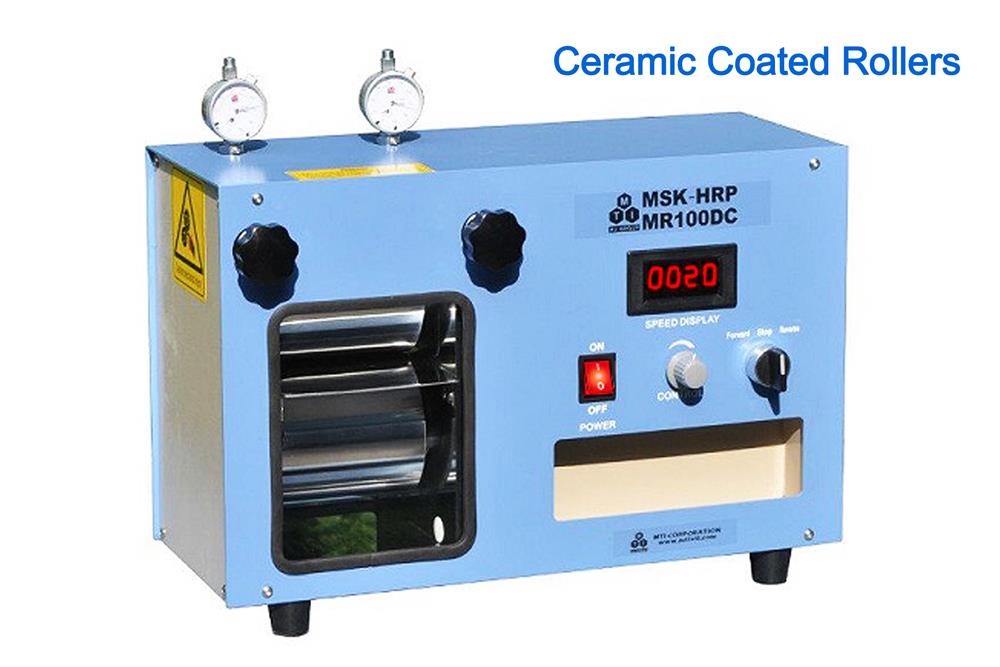

4" Width Electric Cold Roller Press with Optional Ceramic and PTFE Rollers-MSKMR100DC

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

4" Width Electric Cold Roller Press with Optional Ceramic and PTFE Rollers-MSKMR100DC

MTI

MSK-HRP-MR100DC is a UL/CSA ready electric rolling press with variable speed 24VDC gear motor and UL certified switch power supply, which can be used from 110V- 220VAC under Argon gas glovebox. It has dual rollers of 100 mm Dia. x 100mm width and is an ideal rolling press for preparing electrode sheets for Li-Ion batteries research after coating and drying. (Since 11/29/2016, MR100DC ceramic coated roller option is available.)

SPECIFICATIONS:

| Working Voltage |

|

||||||||||||||||

| Motor |

|

||||||||||||||||

| Rolling Speed |

|

||||||||||||||||

| Roller Gap |

|

||||||||||||||||

|

|||||||||||||||||

| Roll to Roll System (Not included) |

R2R device can be integrated with the calendaring machine at extra cost to enable the automatic film unwinding -> winding after calendaring. Please click underline to view product details. |

||||||||||||||||

| Compliance |

|

||||||||||||||||

| Application Notes |

|

||||||||||||||||

|

Warnings |

|