MTI | SKU:

MSK-HRP-300

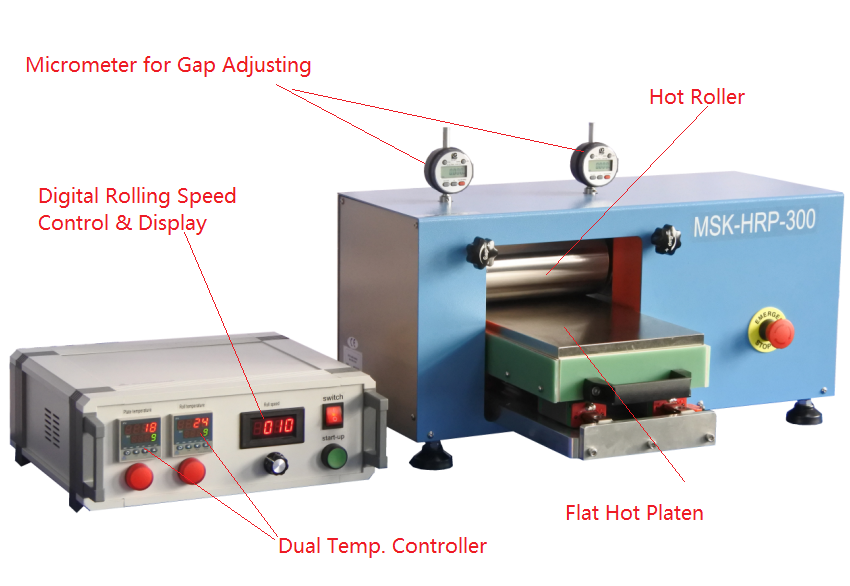

200°C Max Electric Roll to Plate Hot Press (220 mm Width, Ar Gas Compatible) - MSK-HRP-300

€0,00

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

200°C Max Electric Roll to Plate Hot Press (220 mm Width, Ar Gas Compatible) - MSK-HRP-300

MTI

MSK-HRP-300 (updated from MSK-H2150-RP300) is a special Roll-to-Plate hot press with a working temperature of up to 200C. The hot roll drives hot pate via DC motor to achieve flat pressing, which is designed for better laminating multilayer material, also making dry electrodes for the rechargeable batteries.

SPECIFICATIONS:

| Power |

|

Roller Material & Size |

|

|

Roller Gap ( Thickness ) |

|

|

Dial Gauge Accuracy |

|

|

|

|

|

|

|

Power |

|

|

Motor (Ar Gas Glove Box Compatible) |

|

|

Output Thickness |

|

|

Compliance |

|

| Warnings |

|