MTI | SKU:

DIE15SiN

Silicon Nitride Pressing Die optional 12/15/20/25 mm I.D. for Hot Pressing up to 1050C - DIE-SiN-XX

€944,35

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Silicon Nitride Pressing Die optional 12/15/20/25 mm I.D. for Hot Pressing up to 1050C - DIE-SiN-XX

MTI

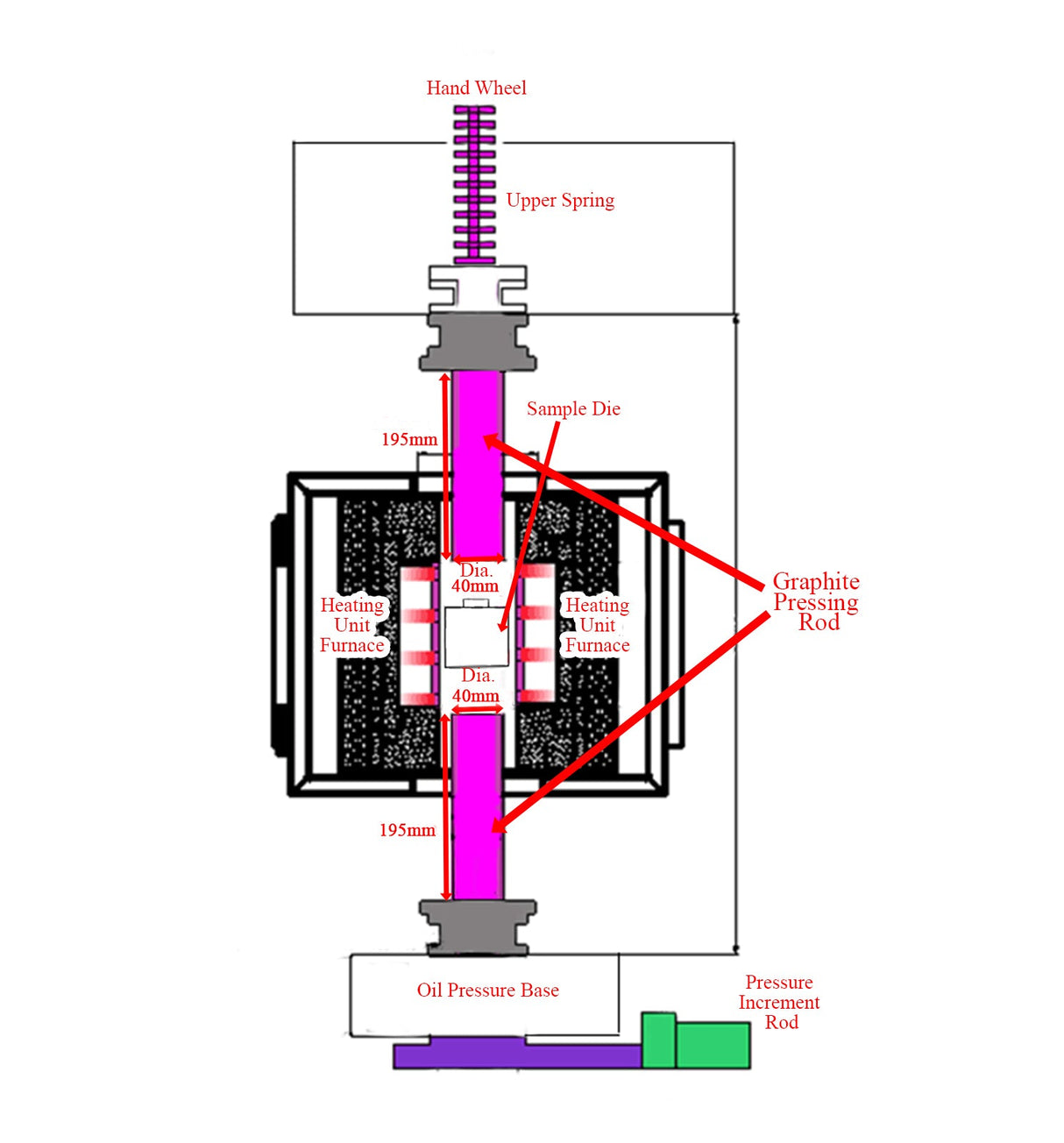

DIE-SiN-XX is the dry pressing die made of silicon nitride (Si3N4) with a pressure of 150MPa max. and a working temperature of 1050°C Max

SPECIFICATIONS:

| Material |

Made of high-purity silicon nitride (Si3N4) |

The whole set die includes  |

|

|

Steps to make a sample pellet |

|

| Instruction Video |

|

| Cautions |

|