1.6T Lamination Press 200C w/ Precision Pressure Controller Optional 12x12" or 20"x20" - YLJ-HP-200L

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

1.6T Lamination Press 200C w/ Precision Pressure Controller Optional 12x12" or 20"x20" - YLJ-HP-200L

MTI

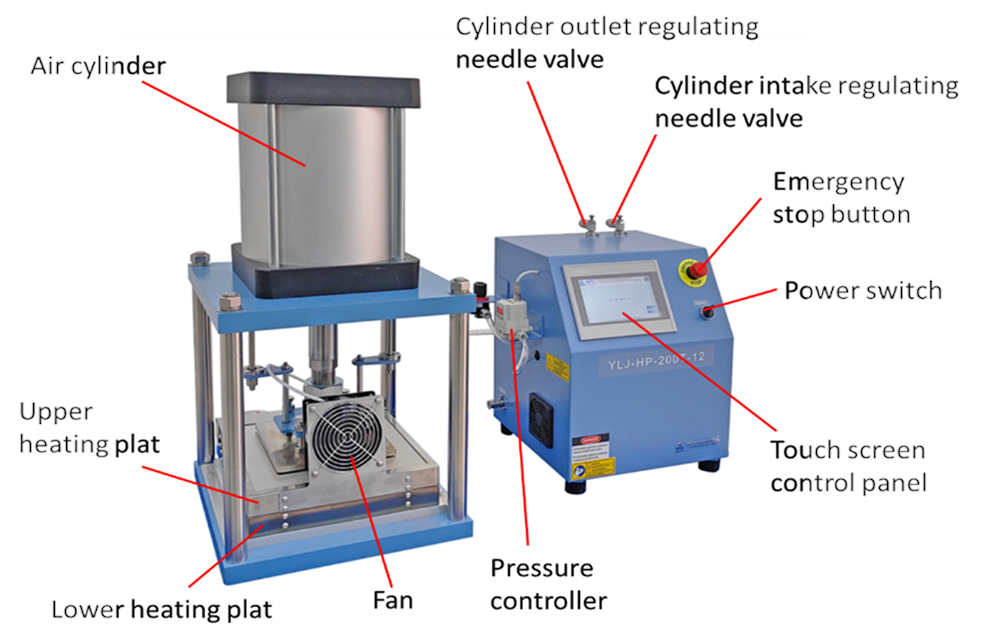

YLJ-HP-200T series Pneumatic Hot Press equipped with a precision constant pressure controller within +/- 0.5 kg up to 1.6T and 200°C. It is designed for testing the effect of pressure on solid-state battery performance, and also can be used for the SEI formation and lamination of solid-state battery electrodes under hot pressing. This device is Ar gas compatible and can be used in the glove box.

| Pneumatic Press |

|

| Heating Plates |

|

| Pressure Controller |

|

| Control Panel |

|

| Compliance |

|

| Net Weight | 190 kg |

| Shipping Weight | 350 kg |