MTI | SKU:

MSK-USP-6000

Lab Spray Dryer up to 300C with Glass Chambers - MSK-USP-6000

€0,00

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

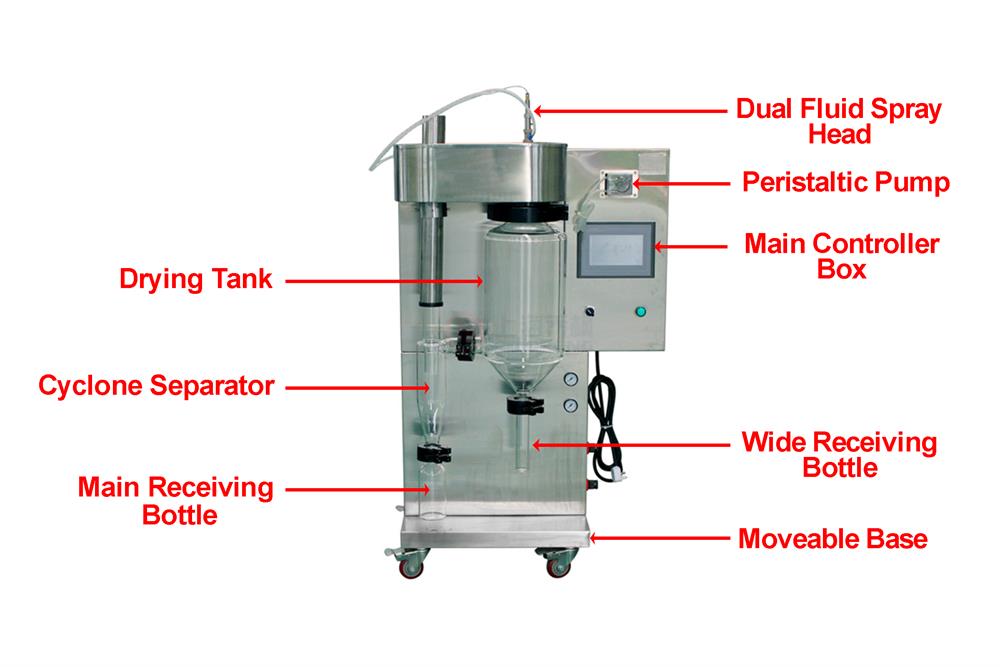

Lab Spray Dryer up to 300C with Glass Chambers - MSK-USP-6000

MTI

MSK-USP-6000 is a lab-scale spray dryer that generates fine particles by evaporating the atomized liquid spray and that has been collected through the cyclone separating process. It is suitable for synthesizing heat-sensitive materials for a broad range of applications such as Pharmaceuticals, Nanotechnology, Catalysts, Fuel cells, and Batteries.

SPECIFICATIONS