5.5 KW Wire Pressing Machine with Winding Roller For Metallic Wire from 10mm to 1 mm - YLJ-1220-W

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

5.5 KW Wire Pressing Machine with Winding Roller For Metallic Wire from 10mm to 1 mm - YLJ-1220-W

MTI

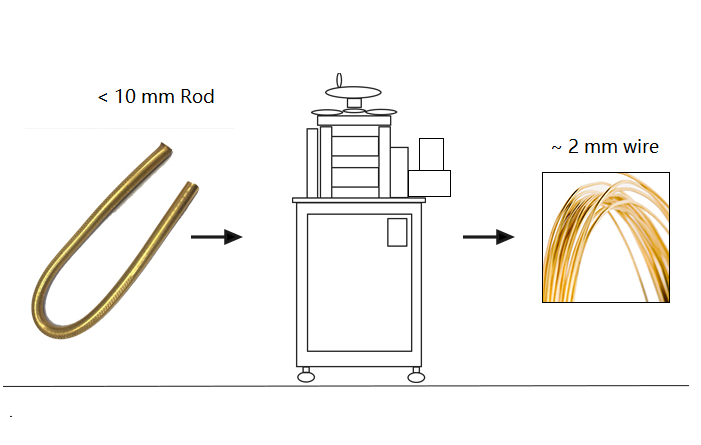

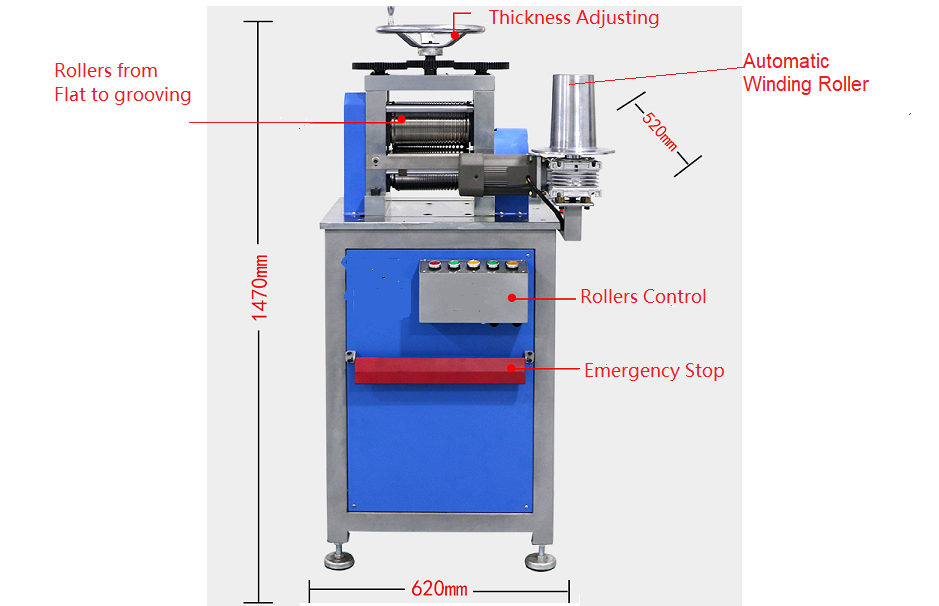

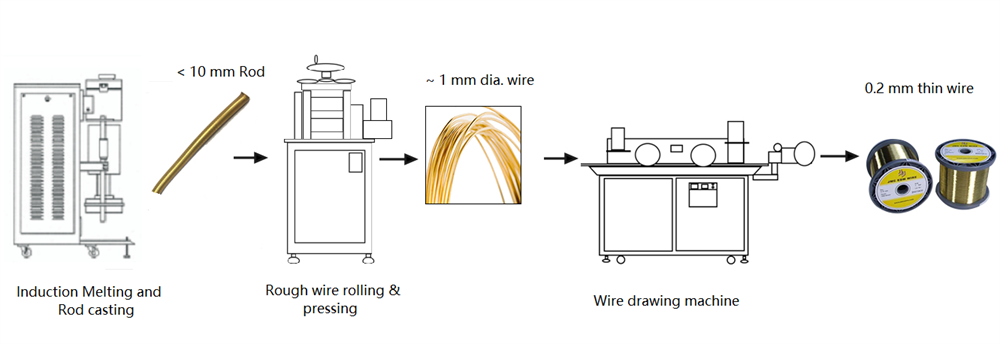

MSK-1220-W is a heavy-duty electric rolling press with 5.5 KW, which is designed for rolling metallic wire from ? 10 mm rod or bulk (< RC 50) to 1 mm diameter, such as Aluminium alloy, Copper, Nickel alloy and stainless steel, etc. This device is one of necessary for wire preparation of metallic wire for AM ( Click here to see details)

SPECIFICATIONS: