MTI | SKU:

VMC-1200

1200ºC Max. High Vacuum Melting-Casting Furnace with Stirring & Secondary Charge Function - VMC-1200

€0,00

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

1200ºC Max. High Vacuum Melting-Casting Furnace with Stirring & Secondary Charge Function - VMC-1200

MTI

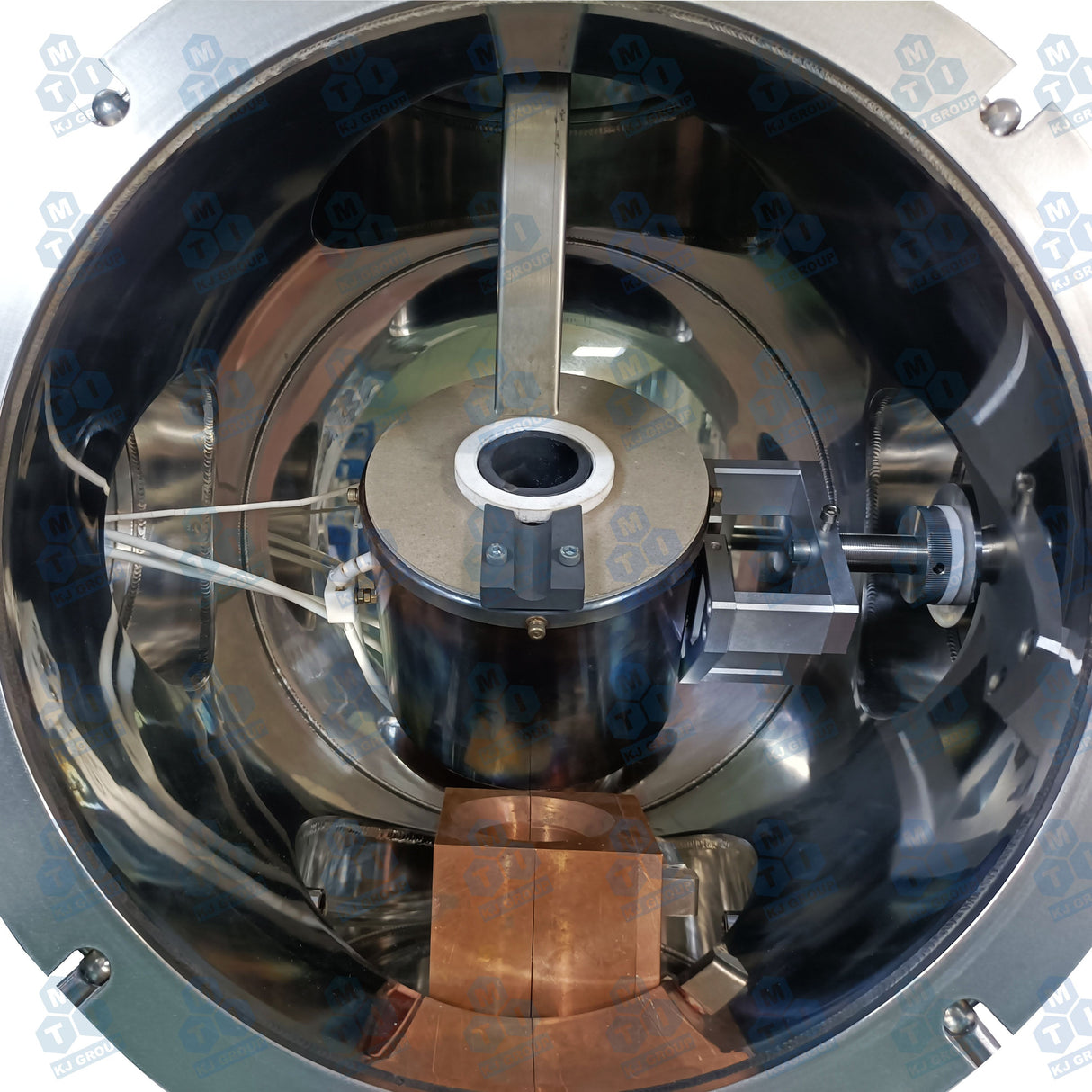

VMC-1200 is a vacuum melting & casting furnace with stirring & secondary charge function that is capable of melting/casting various metal alloys up to 1000g (Fe as reference) at Max. 1200ºC. It is an excellent furnace for preparing various light metallic alloys, such as, Li, Al, Mg alloys, thermal electronics alloys, and phase transformation energy storage. This furnace is also excellent for preparing alloys of lithium anode, such as Li–3Al–1Yb electrode shown in the paper.

SPECIFICATIONS:

| Power Requirements |

|

|

Vacuum chamber |

|

| Crucible & Casting Mold |

|

| Heating & Temperature controller |

|

|

Pressure Gauge & Flow meter |

|

|

Vacuum and Pressure |

|

| Compliance |

|