Arc Melting System up to 300g with Electromagnetic Stirring and Vacuum Casting - SP-MSM-300

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Arc Melting System up to 300g with Electromagnetic Stirring and Vacuum Casting - SP-MSM-300

MTI

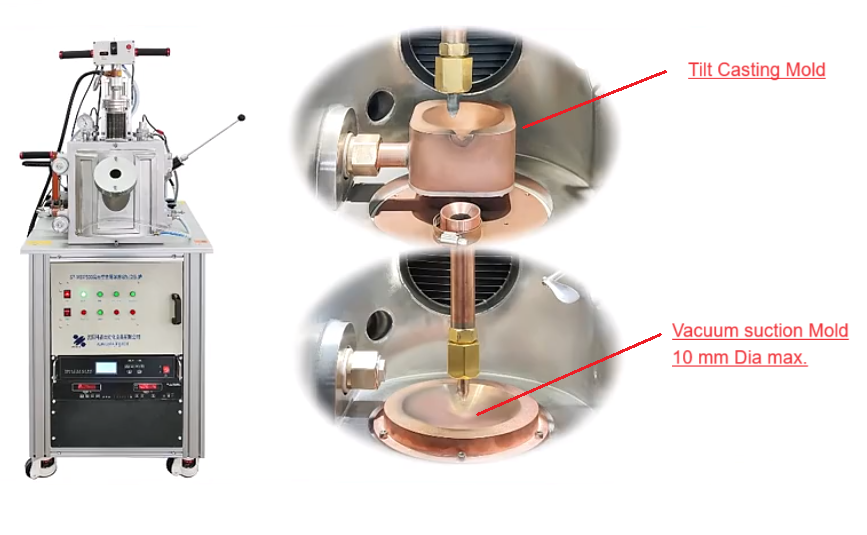

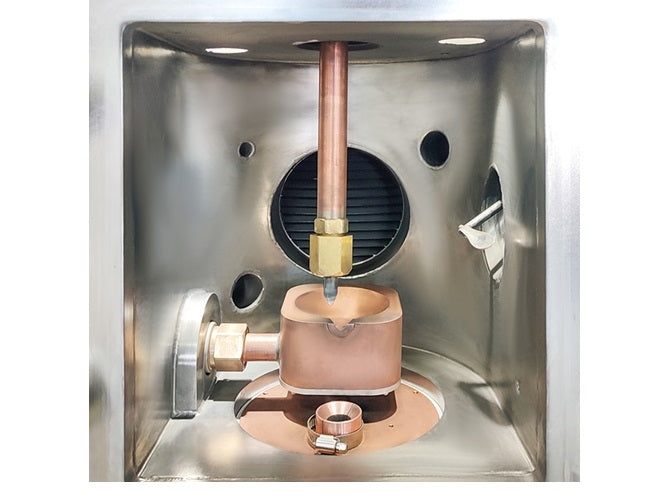

SP-MSM-300 is a complete turn-key arc-melting system with a water-cooled high vacuum chamber, melting cavities, vacuum casting, and electromagnetic stirring for up to 300 g steel. It allows researchers to explore the next generation of alloy.

Features?

- Water-cooled stainless steel vacuum chamber with a vacuum of 10^-6 torr

-

630 A arc melting power supp with arc ignition without contact of sample

-

Water-cooled copper hearth with multiple cavities for multiple samples and gettering.

-

Adjustable arc electrode to melt multiples samples easily and uniformly.

- A wobble stick is built-in for sample flipping without breaking vacuum

- Interchangeable copper hearths with electromagnetic stirring or vacuum casting.

| Power Supply |

|

| Melting Chamber |

|

|

Water-cooled Copper Hearth |

Two types of water-cooled copper hearths

|

|

Tungsten Electrode |

|

|

|

| Pressure Gauge | |

|

Vacuum System (Optional) |

|

Water Chiller (Optional)

|

|

| Working Gas (Optional) |

|

| Compliance |

|