MTI | SKU:

IMCS-1700HP

Hi-Pressure Induction Melting-Casting or Infiltrating System (1 Mpa @ 1700C Max.) - IMCS-1700HP

€0,00

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Hi-Pressure Induction Melting-Casting or Infiltrating System (1 Mpa @ 1700C Max.) - IMCS-1700HP

MTI

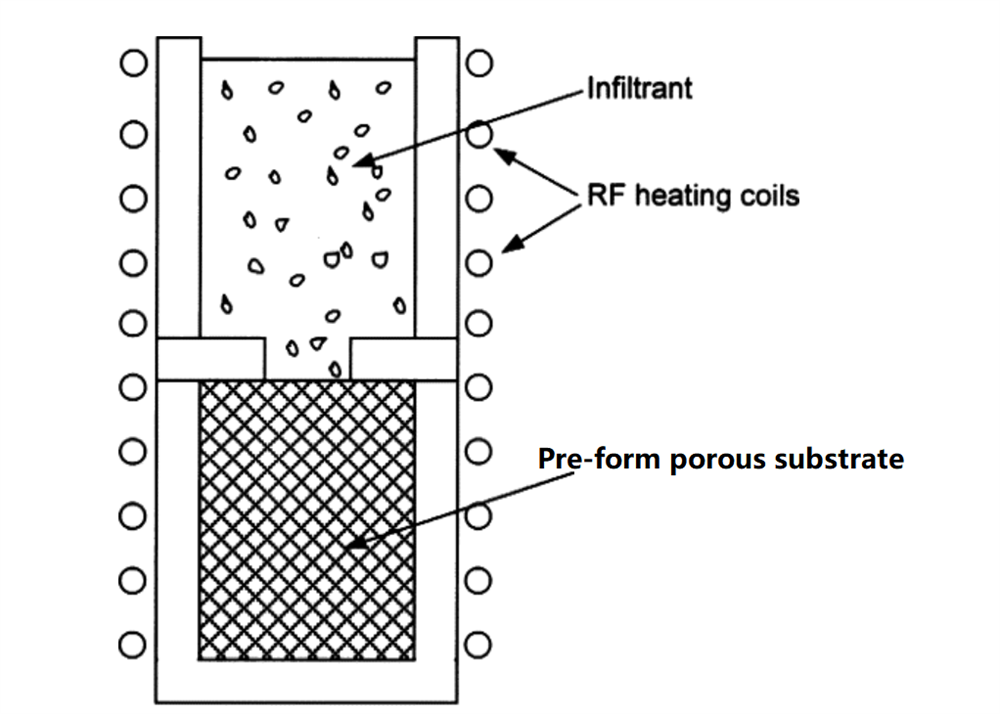

IMCS-1700HP is a High-Pressure induction melting/casting furnace which can granulate various alloys up to 2 kg at Max. 1700ºC under high-pressure Ar gases up to 10 bars, and also can be used to separate melt from slag or make composite by melt infiltration

SPECIFICATIONS:

SPECIFICATIONS:

Induction Heating Power Source |

|

Melting Chamber ( Top)  |

|

Temperature Control |

|

Casting Chamber ( Bottom )  |

|

| Crucible |

|

| Warranty |

|

| Compliance |

|

| Warning |

|

| Dimensions |

|

| Operation Video |

|

| Net Weight |

200kg |

| Shipping Weight | 300kg |