Atmosphere Controlled Continuous Casting Furnace with Secondary Charge Function - IMCS-1700VC

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Atmosphere Controlled Continuous Casting Furnace with Secondary Charge Function - IMCS-1700VC

MTI

IMCS-1700VC is an induction melting and continuous casting furnace under vacuum or inner gas, which can cast the rod, plate, or wire continuously for various alloys up to 5 kg at Max. 1700ºC . This device is necessary for wire preparation of metallic wire for AM ( Click here to see details)

SPECIFICATIONS:

- One set of standard graphite crucibles with thermal insulation is included for melting and solidification

- Graphite crucible dimension: 160 ID * 220H (mm) ~2 Liter

- Max. melting capacity 5 kg ( Stainless steel based )

- Max. Melting point: 1700ºC

- Air-tight chamber in the bottom of the melting chamber with pulling down mechanism

- Pulling speed: 8 - 10 0cm/min adjustable

- Types and sizes of castable profiles (Please discuss this with our engineer for your application before purchasing it.)

- Graphite lower mold: M50 * 150mm

- Protective Gas: argon, nitrogen with a purity of 9999 (2L per hour needed)

| Power Requirements |

|

Melting Chamber Stainless steel chamber with Secondary charge and stiring function. Stainless steel chamber with Secondary charge and stiring function. |

|

Casting

|

|

| Temperature Control |

|

Vacuum and Inert Gas |

|

Water Cooling  |

|

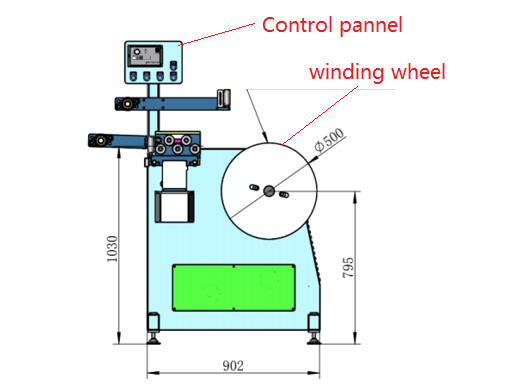

Winding device (optional) |

|

| Warranty | One-year limited warranty with lifetime support |

| Compliance | CE certified NRTL certification is available upon request at an extra cost |

| Dimensions |

|

| Net Weight |

350kg |

| Shipping Weight | 500kg |

Operation Video  |

Melting & Casting Demo ( vacuum casting) |