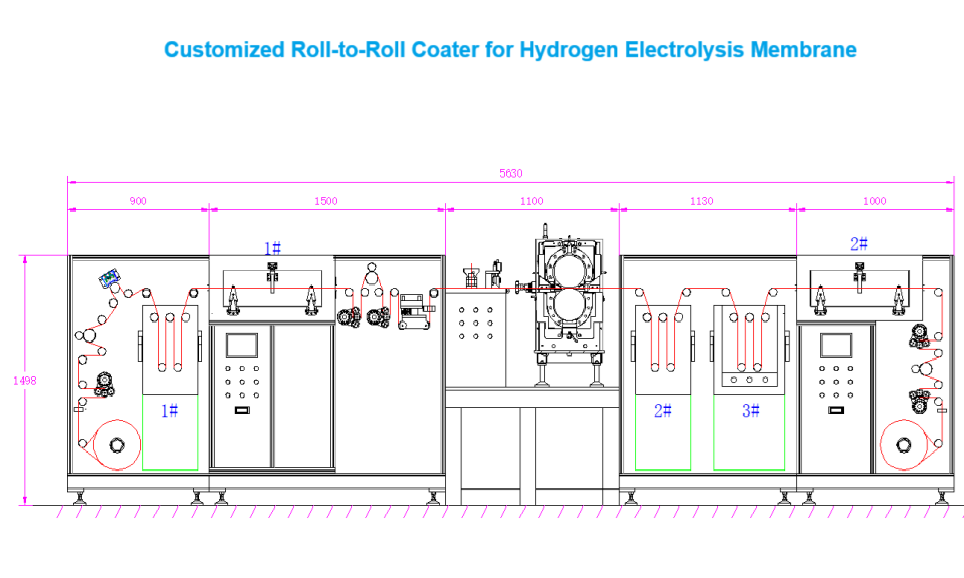

R2R Membrane Coating System For Hydrogen Electrolysis or Desalination -MSK-FPI-R200

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

R2R Membrane Coating System For Hydrogen Electrolysis or Desalination -MSK-FPI-R200

MTI

MTI designs and manufactures the customized roll-to-roll membrane coating system for hydrogen electrolysis or seawater desalination

Technical Processes, including, but not limited, to below:

(1) The substrate will be released from the unwinding roller and processed by a corona treatment after unwinding to obtain a hydrophilic surface ;

(2) The substrate will be sent to a bath for dip coating with hydrophobic repellents (room temperature) and then dried in an IR heating chamber (Max.80?);

(3) The powders were vibrantly dispersed on the coated substrate, flattened by a blade, and rolled pressed by a hot calender;

(4) Enter into the washing bath at room temperature;

(5) Enter into the slurry bath for dip coating under 60-80?; (6) Enter into the IR heating chamber for drying (80-120?); (7) Winding.

SPECIFICATIONS:

|

Power & Voltage |

|