Compact Roll to Roll Coater w/ 160mm Max. Width & 6 Optional Coating Heads (Combination)-MSKAFAEI200

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Compact Roll to Roll Coater w/ 160mm Max. Width & 6 Optional Coating Heads (Combination)-MSKAFAEI200

MTI

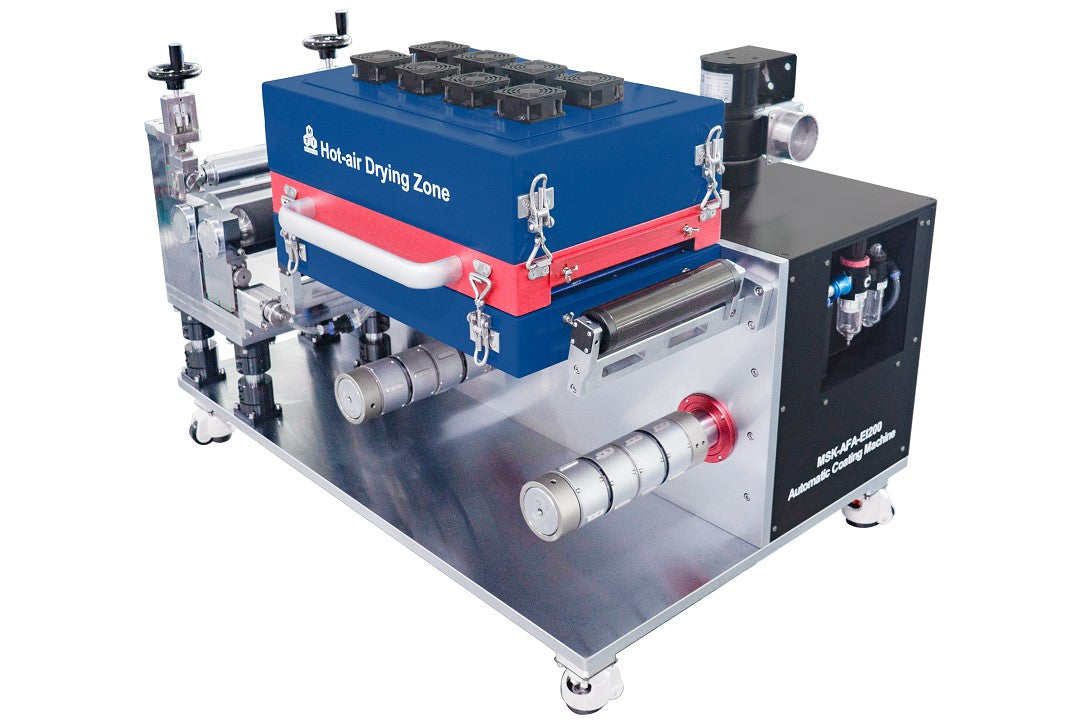

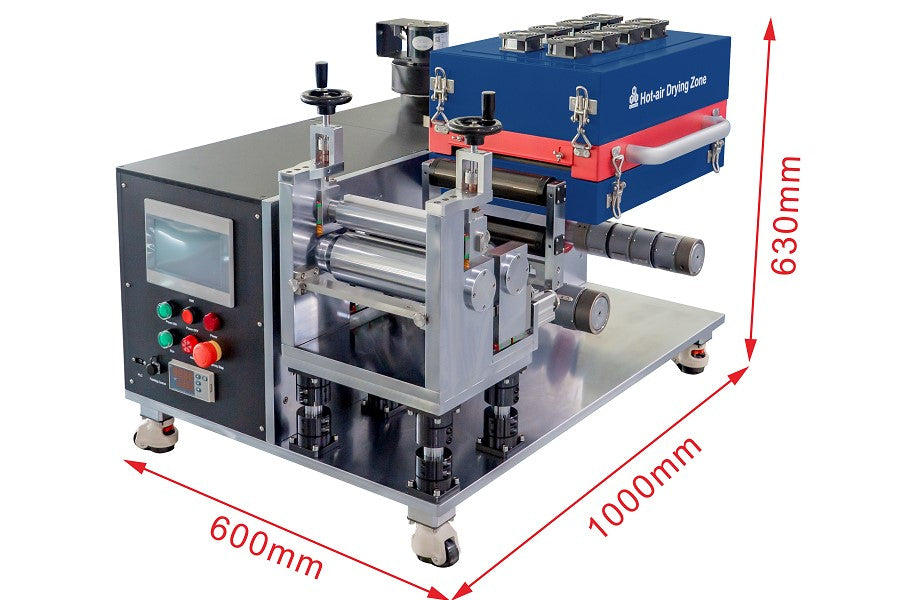

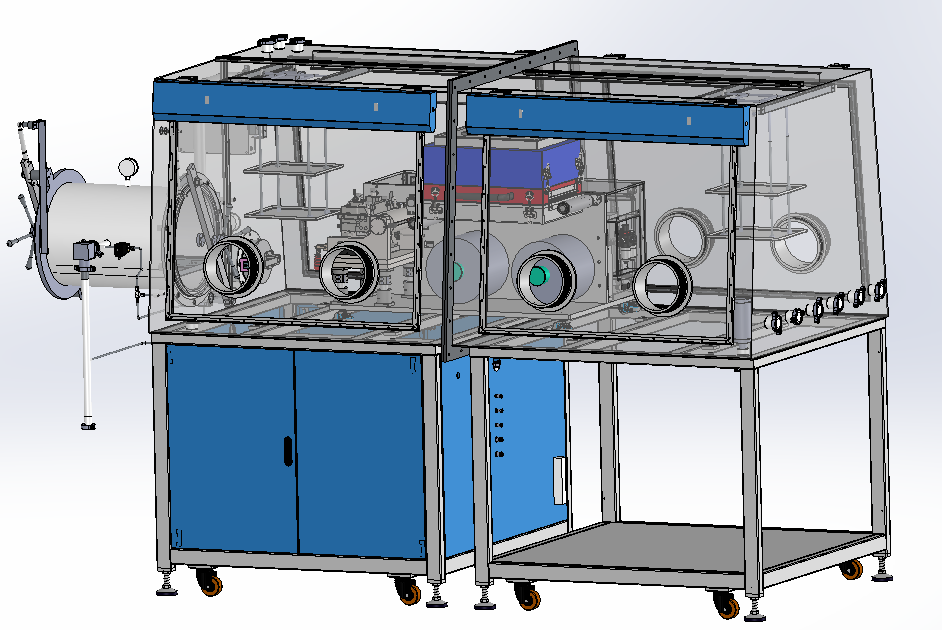

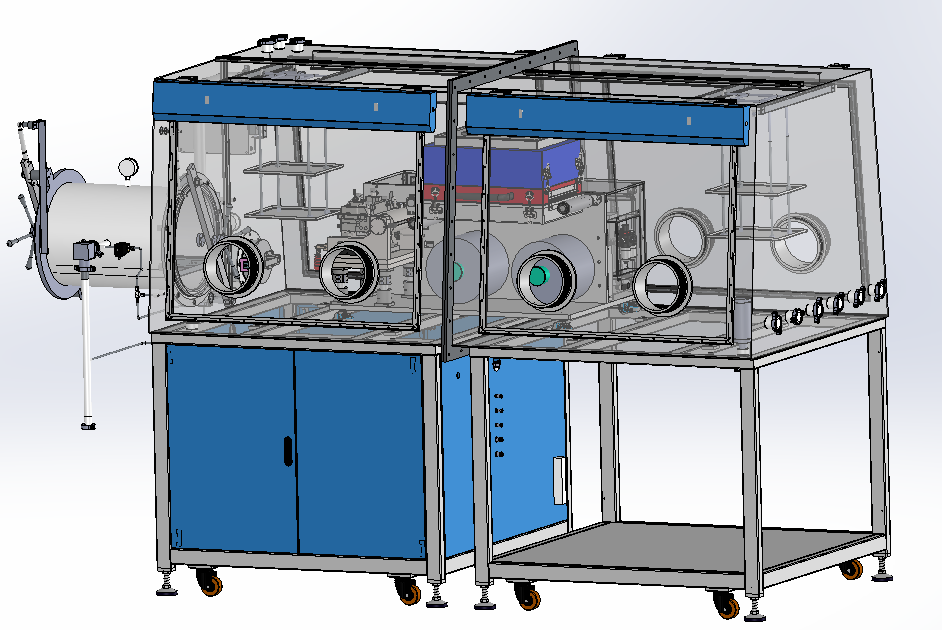

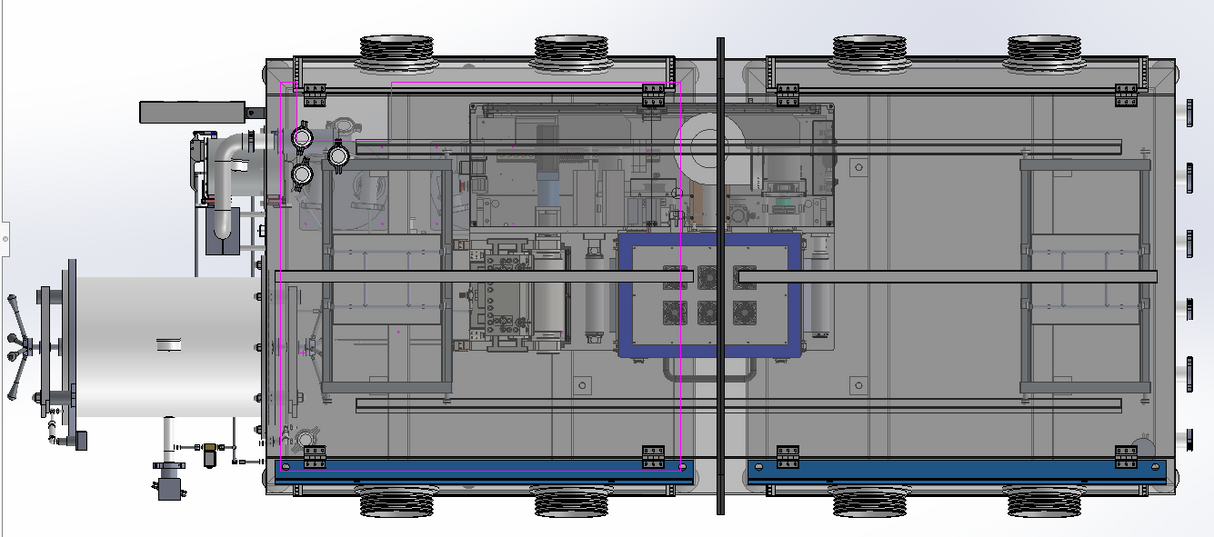

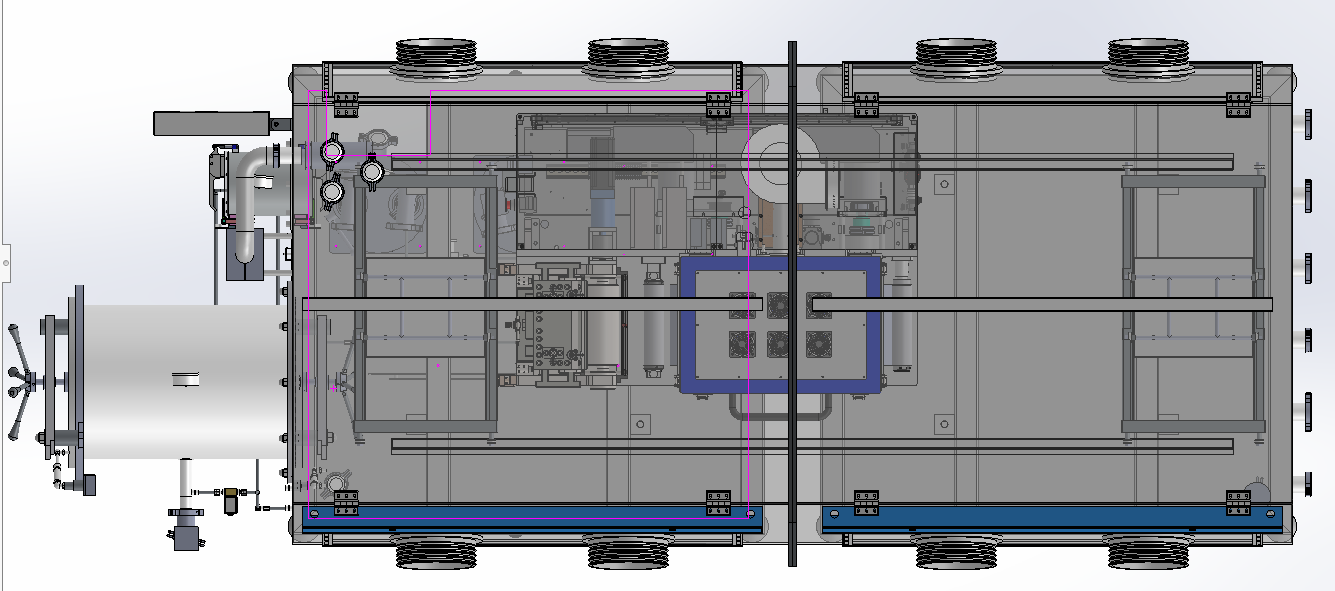

MSK-AFA-200 is a Roll-to-Roll continuous coat with 6 optional coating heads or head combinations for film coating with a small footprint for materials research labs.

This system integrates the functions/ features of reeling in & out, slurry feeder, coating blade, baking oven, and final electrode winding (reeling in).

It can coat electrode sheets up to 160mm in width and 500 meters in length automatically.

For Roll to Roll Coater Service, please fill out and submit the Roll to Roll Coating Service Request Form

Note: upgraded to 4 coating heads option since Nov. 15, 2021

SPECIFICATIONS:

|

Power |

|

|

|

6 Type of Coating Heads Optional (5) Slot Die + Doctor Blade Coating (6) Slot DIe + Reverse Comma Blade Coating |

Please select the option bars to choose the coating head/combination (1) Doctor Blade Coating; Thickness Precision: +/- 0.006 mm (2) Reverse Comma Blade ( Transforming ) (3) Micro-Gravure Coating |

(4) Slot Die Coating: (5) Slot Die + Doctor Blade Coating (6) Slot DIe + Reverse Comma Blade Coating |

|

Coating Width |

|

|

|

Coating thickness |

For bilayer slot die coating, please consider the customized slot die head with dual channels:

|

|

|

Coating Speed |

|

|

|

Heating |

|

|

|

Reeling/Unreeling |

|

|

|

Max. Coating Length |

|

|

|

Slurry Feeding (Optional) |

|

|

|

Guild Roller |

|

|

|

Compliance |

|

|

|

Application Notes |

|

|

| Optional |

Pic.1 Pic.1  Pic.2 Pic.2  Pic.3 Pic.3  Pic.5 Pic.5 |

|