MTI | SKU:

MSK-SP-H2

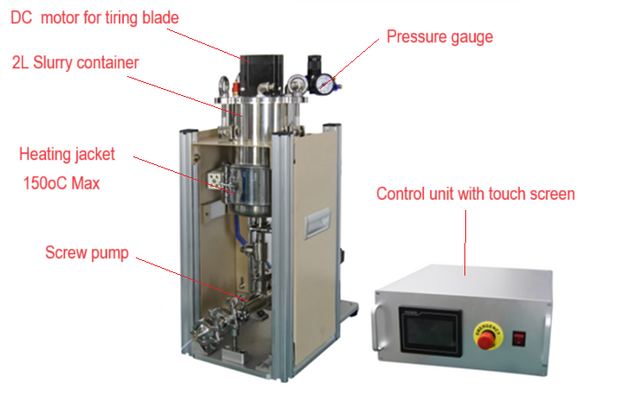

2L Precision Slurry Feeder with Stirring & Vacuum & Heating Functions (150oC Max) - MSK-SP-H2

€0,00

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

2L Precision Slurry Feeder with Stirring & Vacuum & Heating Functions (150oC Max) - MSK-SP-H2

MTI

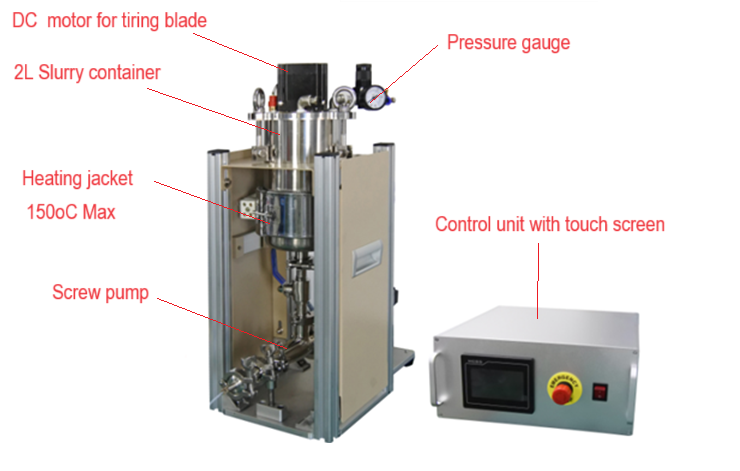

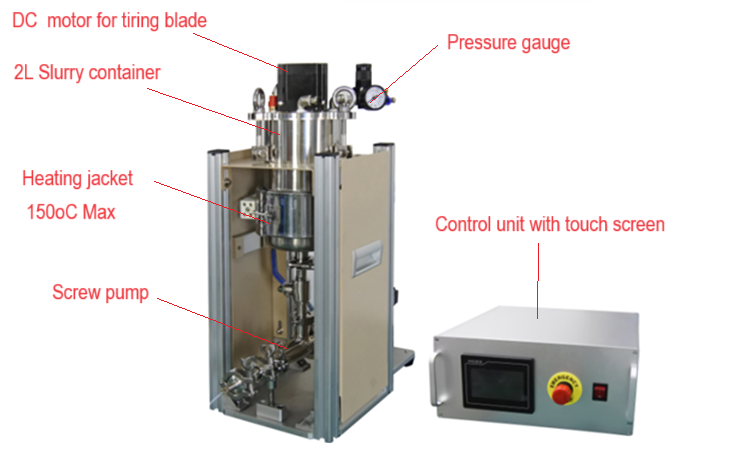

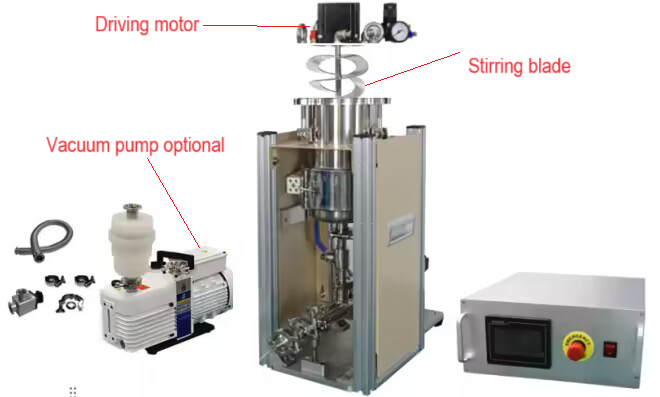

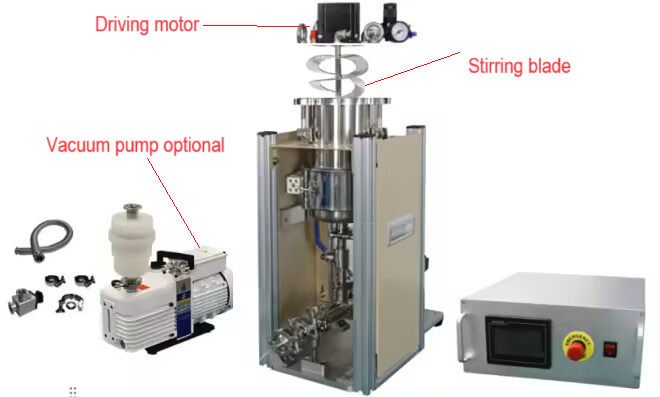

MSK-SP-H2 is a precision slurry feeder delivered by a screw pump with 2000 mL air-tight stainless steel container. The container is heat able up to 150oC

with digital temperature control. A stirring blade is inside chamber to mix slurry under either vacuum or positive pressure condition. It is designed for delver slurry

precisinly for roll to roll Slot-die coating, and also can be used for mixing slorry before coating. It is multi-function tool for preparing various film for poly , ceramics

and electrodes of lithium ion batter.

SPECIFICATIONS:

|

Features |

|

| Power |

|

Slurry Container |

|

| Screw Pump |

|

Touch-Screen Control Panel |

|

| Options |

|