MTI | SKU:

MSK-HTBA

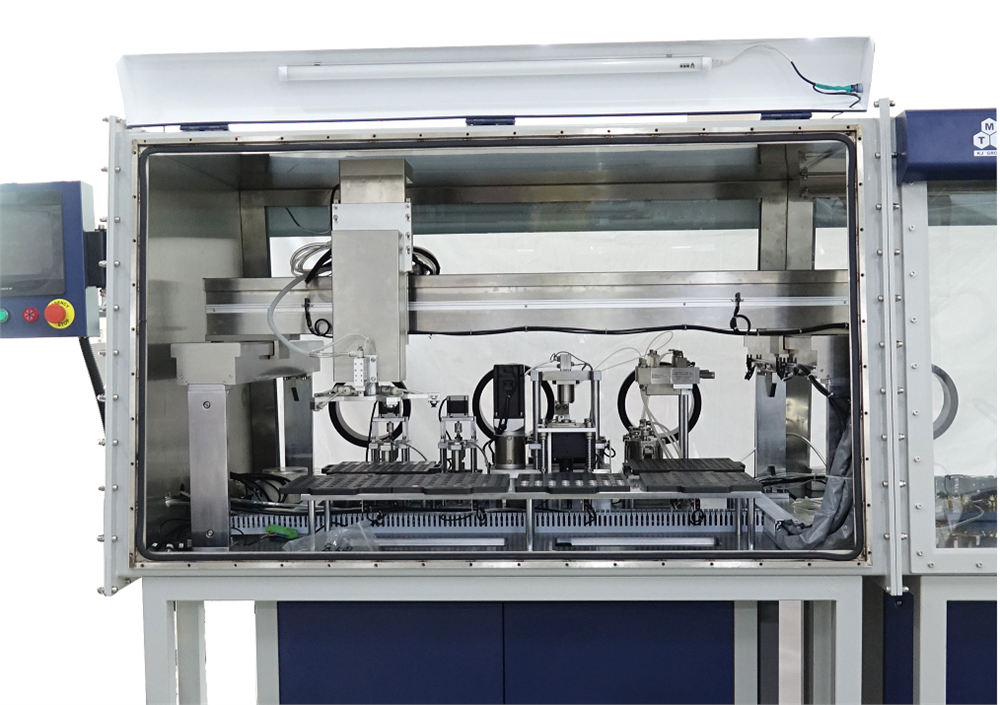

High Throughput Coin Cell Assembling System Up to 64 Cells Per Hour For Battery Research - MSK-HTBA

€0,00

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

High Throughput Coin Cell Assembling System Up to 64 Cells Per Hour For Battery Research - MSK-HTBA

MTI

MSK-HTBA is an automatic coin cell assembling system for high throughput battery material research, which can handle 8 kinds of battery cathode and the anode electrode and 2 kinds of electrolytes and assemblies 64 cells per hour in dual size glove-box with under controlled atmosphere.

Features |

|

|

Flow Chart

|

|

|

| Voltage & Power |

|

|

| Utility Requirements |

|

|

| Battery Materials Requirements |

|

|

Modules

|

|

|

| Coin Cell Type |

|

|

| Channels |

|

|

| Production Yield |

|

|

| Accuracy |

|

|

| Dimensions & Net weight |

|

|

Optional

|

|

|

| Compliance |

|

|

| Optional |

|