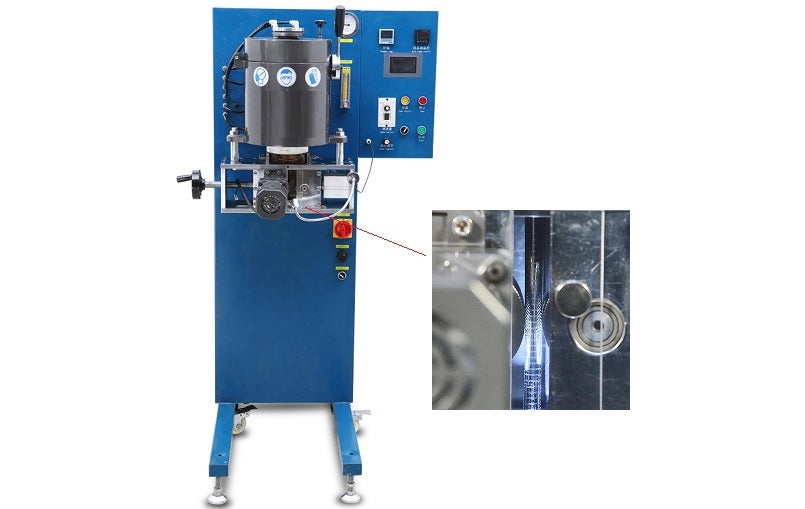

Atmosphere Controlled Directional Solidification System with Optional Feeding Device - IMCS-1500RC

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Atmosphere Controlled Directional Solidification System with Optional Feeding Device - IMCS-1500RC

MTI

IMCS-1500RC is an induction melting and continuous casting furnace, which can cast the rod, plate or wire continuously for various non-ferrous metals and alloys up to 5 kg at Max. 1500ºC under the Ar gases environment. This device is necessary for wire preparation of metallic wire for AM ( Click here to see details)

SPECIFICATIONS: