MTI | SKU:

SKJ1200BG

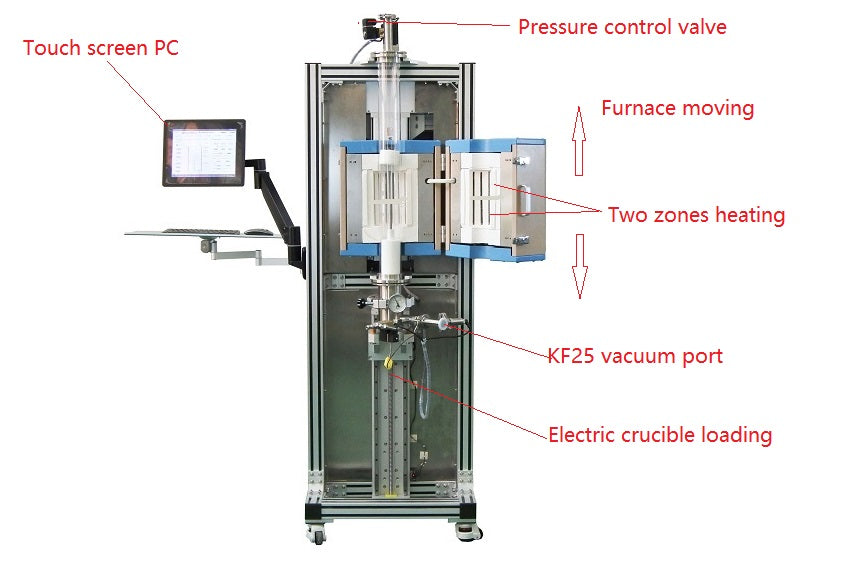

1200°C Max. Small Bridgman Crystal Growth Furnace with Air-tight 80 mm Quartz Tube - SKJ-BG-1200

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

1200°C Max. Small Bridgman Crystal Growth Furnace with Air-tight 80 mm Quartz Tube - SKJ-BG-1200

MTI

SKJ-BG-1200 is a small 1200ºC Bridgman crystal growth furnace with a 72 mm ID quartz tube and precision travel mechanism, which is designed for growing small size crystals under control atmosphere up to 1200oC

SPECIFICATIONS:

Vertical Two Zone Tube Furnace  |

|

Travel Mechanism |

|

| Airtight Flanges |

|

Control Panel |

|

| Optional |

|

| Product Dimensions |  |

| Compliance |

|

| Warranty |

|

| Operation Demo Video |

|

| Application Notes |

|

| Net Weight | 105 kg (230 lbs) |

| Shipping Weight | |

| Shipping Dimensions |