Hi-Throughput Hot Rolling Machine (32 Sample/Batch) for Research of Alloy Deformation Strengthening -MSK-HRP-MG1

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Hi-Throughput Hot Rolling Machine (32 Sample/Batch) for Research of Alloy Deformation Strengthening -MSK-HRP-MG1

MTI

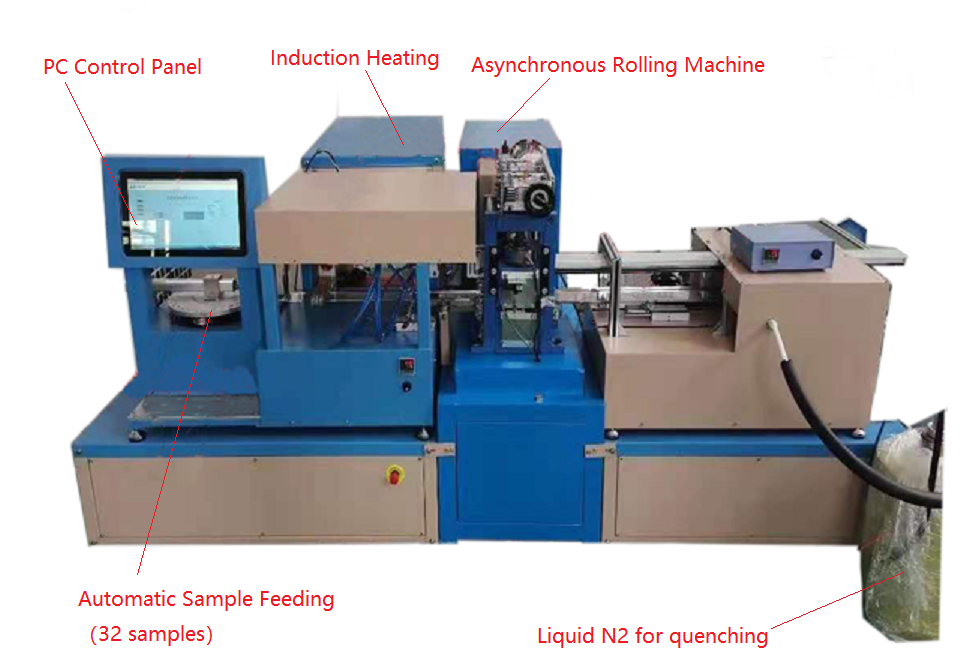

MSK-HRP-MG1 is a lab-scale automatic hot rolling machine for high throughput research of metallic alloy strengthening via deformation. It can roll 32 samples continuously via a PC program at the different rolling temperatures ( up to 950oC) , rolling amounts, rolling times, and cooling temperatures by touch one button.

SPECIFICATIONS