MTI | SKU:

MSK-521

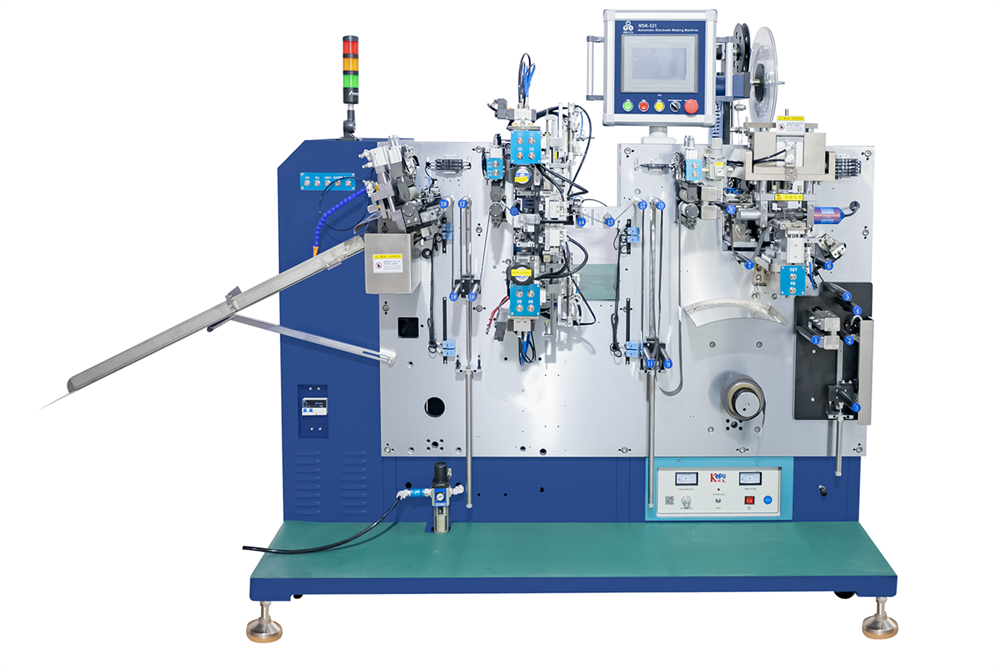

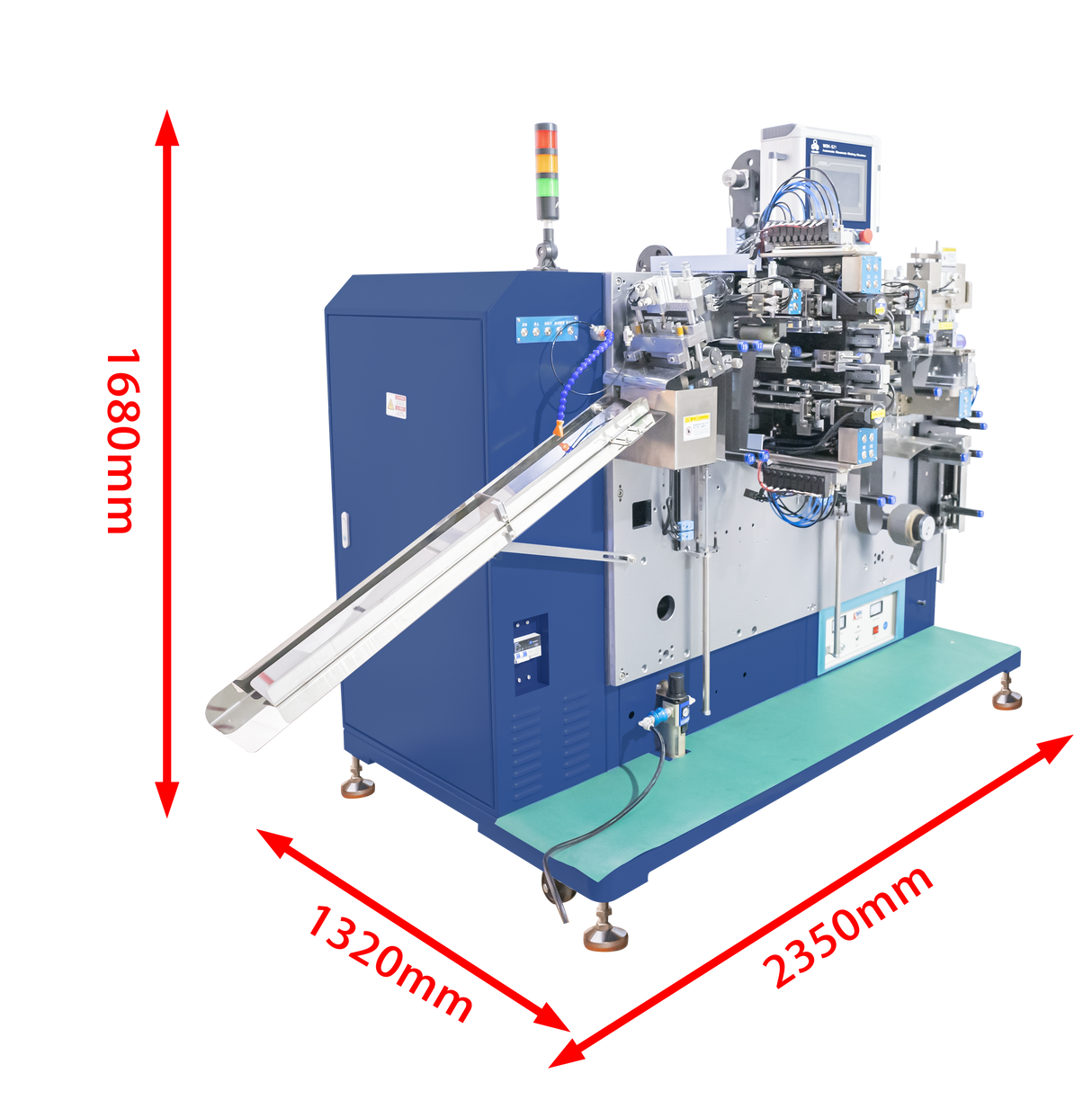

Automatic Roll-to-Stripe Slitting Machine with Integrated Functions of Electrode Cutting, Tab Welding, and Taping-MSK-521

€0,00

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Automatic Roll-to-Stripe Slitting Machine with Integrated Functions of Electrode Cutting, Tab Welding, and Taping-MSK-521

MTI

Outstanding Features:

- Auto-tension control.

- Continuous fixed-length cutting mode

- Minor adjustment at the cutting edge for the continuous cutting

- Automatic tab welding and taping function is integrated with electrode cutting

- PLC Touch screen control panel

MTI has granted the patent 201821974061.8 for the Automatic Slitting Machine MSK-520/MSK-521 series since September 2019.

SPECIFICATIONS:

| Working Voltage |

|

| Feeding Material Requirements |

|

| Winding Alignment |

|

| Cutting Position Accuracy |

|

| Tab Welding Tensile Force |

|

| Tab length outside of trail |

|

| Part Lifetime |

|

| Compress Air Requirement |

|